doylebloss

Supportive Member

(via RSS feed from https://historyofprofessionalcarpetcleaning.wordpress.com)

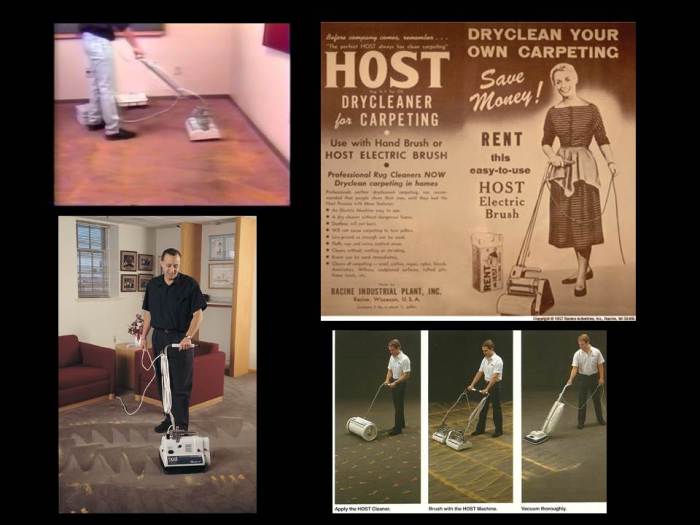

Host/Racine Industries

From the Host website: “Racine Industries, Inc., manufacturer of the HOST Dry Carpet Cleaning System , began as the Rench Manufacturing Company and was founded by Harry Rench in 1936. From the beginning, Racine Industries, Inc. manufactured carpet cleaning equipment and a dry cleaner. The company was the first in the United States to produce non-resoiling detergents for carpet cleaning, rightfully recognizing that animal based soaps left a residue that contributed to rapid resoiling of the carpet.

In the late 1930s, Rench got involved with the Bigelow Sanford company in a patent pool that resulted in the first dry carpet cleaning powder. This dry ‘powder’ was developed in order to solve a problem that arose when water was used on wool carpet. The solvent-based powder was brushed into the carpet with a broom and vacuumed. The ‘powder’ absorbed the soil and held it until vacuumed out.

In 1956, a new dry cleaner for carpets was introduced at the National Institute of Rug Cleaners in New York. This new product worked better than the original ‘powder’ and could be used with a machine. It was a combination of water, detergents, a safe solvent mixed with ‘sponges’ that dissolved and absorbed the soil under control, and allowed for a thorough extraction at the time of cleaning. It was called HOST Dry Extraction Carpet Cleaner. Over the next 50 years, many innovations were added to the original concept.”

For more information: http://www.hostdry.com/about-host-dry-carpet-cleaning/the-history-of-host

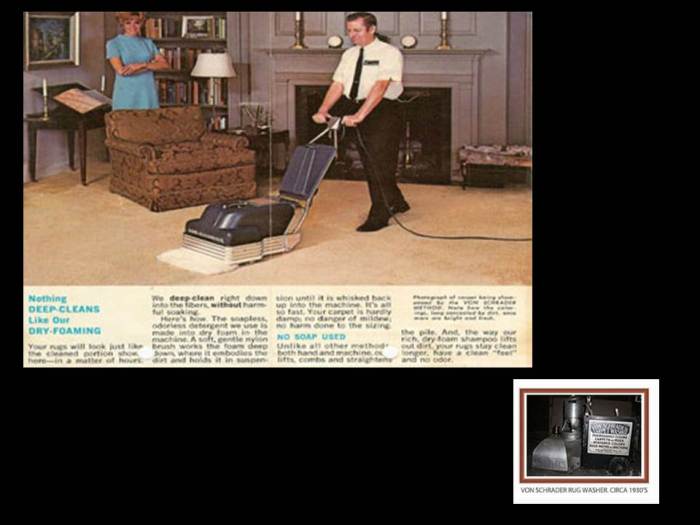

Von Schrader

Although most professional cleaners today know Von Schrader as the leading manufacturer of dry foam carpet cleaning equipment, many may not realize the Von Schrader was certainly one of the first companies to sell running an on-location carpet cleaning business as a way to build a business and a career. According to their web site, “in 1935, in the midst of the Great Depression, an enterprising young man named Francis Von Schrader dreamed of helping people find ways to help themselves. What Fran wanted to sell was not merely carpet cleaning equipment but an opportunity. He believed that if given a chance, industrious individuals could develop and build prosperous, independent businesses.” The company says that since their introduction on the 1930’s, more than 50,000 people have become Von Schrader “Associates.”(Associates are people running their own companies using Von Schrader equipment and programs.)

Von Schrader Upholstery cleaning

Von Schrader introduced what was likely the first professional upholstery only cleaning machine. Using compressed air, it applied a non-resoiling foam to the upholstery fabric that was agitated in with a small rotary brush mechanism.

For more information about Von Schrader, visit their website at ttp://www.vonschrader.com/about-us/our-history

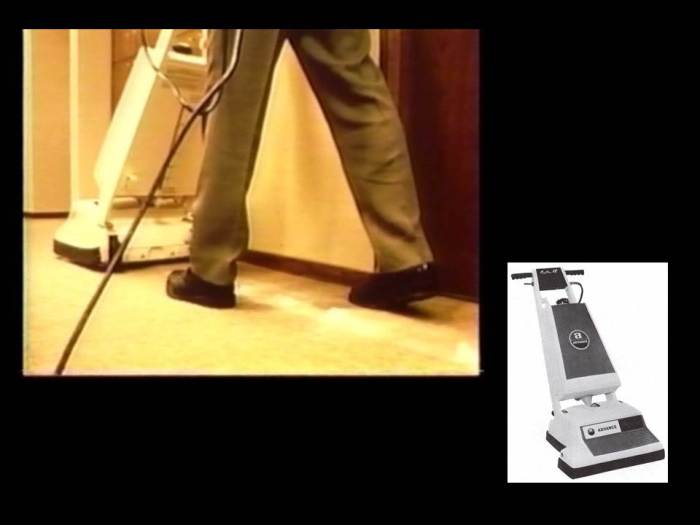

Von Schrader is not the only company that made dry foam shampoo equipment. Advance Machines, now part of Nilfisk manufactured dry foam shampoo application equipment for many years. The first Advance CarpeTron™ dry foam shampooers went into production in 1965.The dry foam method is an effective low moisture, rapid drying carpet cleaning method that has been used in carpet cleaning for decades. The dry foam method is similar to the rotary shampoo method in that brushes are used to agitate the carpet pile. In the dry foam method, an aerator is used to whip the solution in a foam. The foam is dispensed into the horizontally rotating brushes. As with all carpet cleaning methods, the more chemical that is applied, the longer the drying time. Some machines have their own extraction capability. These machines have the capability to remove shampoo and attached soil particles. Other machines do not have extraction capability. A wet/dry vacuum must be used to remove the shampoo and soil.

Bonnet cleaning

Bonnet cleaning has long been one of the most popular carpet cleaning methods, particularly in a commercial carpet setting, and has remained relatively the same since its inception. Bonnet cleaning is a minimum moisture carpet cleaning method. Bonnet cleaning essentially consists of an absorbent cotton, rayon and/or polypropylene pad and an agitation machine. The carpet is generally presprayed with the bonnet cleaning solution, and the cotton, rayon, or polypropylene pad is also moistened with the solution. The pad is attached to the agitation machine. The pad is used to agitate the carpet and to assist in the suspension and absorbance of the soil. Once the pad becomes saturated with soil, it is either rotated to the other side or exchanged for a clean pad. Generally procedures call for post vacuuming once the carpet has dried.

Most bonnet cleaning is done with a rotary floor machine set at a speed of 175rpm. However over the years there have been a wide variety of oscillating and/or orbital agitation machines used with absorbent pads in what could be characterized as bonnet or absorbent cleaning. These pictures were sent to me by John Guerkink of Trinity Carpet Renewal Systems showing a residential cleaning job from 1974 that his father cleaned. Trinity Carpet Renewal Systems utilizes an oscillating agitation rather than rotary.

Other long time bonnet systems have included Argosheen and Ultra-Dry.

Cleaning franchises such as Chem-Dry have, in the past, used variations of the bonnet method with proprietary cleaning solutions over the years. This system today is referred to as the Chem-Dry Legacy System. Many ChemDry Frachises today use a proprietary truckmount hot carbonated solution system.

Many bonnet systems have switched to encapsulation cleaning chemistry utilizing the same agitation machines in the past few years, but with encapsulation chemicals being used instead of traditional bonnet cleaning systems. We will talk more about encapsulation cleaning later.

Rotary shampooing

What do coconuts have to do with professional on-location carpet cleaning?

As on-location professional carpet cleaners began to make their appearance, they began to use a new approach to cleaning carpet. They agitated a bucket of soap and water to form suds and then brushing the suds into the carpet. Coconut oil was the basic ingredient of most detergents at this time that were used to form the suds and toweling with clear water and a touch of ammonia brightened the pile. Later, coconut oil served as the basis for the detergents that were formulated for carpet shampooing utilizing rotary floor machines. The problem with these coconut oil based detergents is that they were sticky and had a tendency to stay in the carpet and act as tacky residue, which could cause the carpet to resoil rapidly after cleaning. This led to the birth of the conception that if you clean you carpets, they will only get dirtier faster. Though coconut oils were replaced by less tacky synthetic detergents in the early 1960’s, the professional cleaning industry to this day has to deal with the misconception usually stated something like this – “Wait as long as you possibly can before you get your carpet cleaned, because once you clean it, it will get dirtier faster.” It does not help that “carpet shampooing” still serves as a generic description for carpet cleaning, even though carpet shampooing has not been the dominant professional on-location carpet cleaning method since the early 1970’s.

In the 1940’s there was not much development in carpet cleaning equipment, chemicals, nor procedures. Much of the world was involved in World War II. Most able bodied men were in the military, and most manufacturing was adapted to meet the needs of military production.

After the war ended, there was an influx of new “talent” into the cleaning business as returning GI’s tried to find a profession. The late 1940’s and early 1950’s were the birthdates of many commercial janitorial companies. “On-Location Professional carpet cleaning in the residential market was still greatly limited to the very wealthy. Through this period, most professional carpet cleaning was done by the rotary shampoo method.

Wet shampoo cleaning with rotary floor machines (175 rpm), involved the application of a foaming detergent into the carpet that was agitated in with a broken in shampoo brush. In most cases, this was followed by thorough wet vacuuming with a wet-dry vacuum. As previously mentioned, these wet shampoos were originally formulated from coconut oil soaps, which meant that the wet shampoo residues would be sticky. Since no rinse or extraction was performed, the powerful residue can continue to collect dirt after cleaning, When wet-shampoo chemistry standards converted from coconut oil soaps to synthetic detergents (usually sodium laurel sulfate) as a base, the shampoos dried to a powder, and loosened dirt would attach to the powder components, requiring vacuuming by the consumer the day after cleaning. The rotary shampoo method remained the most popular way to professionally clean carpet on location until the advent of hot water extraction machines in the 1960’s.

Pile lifter

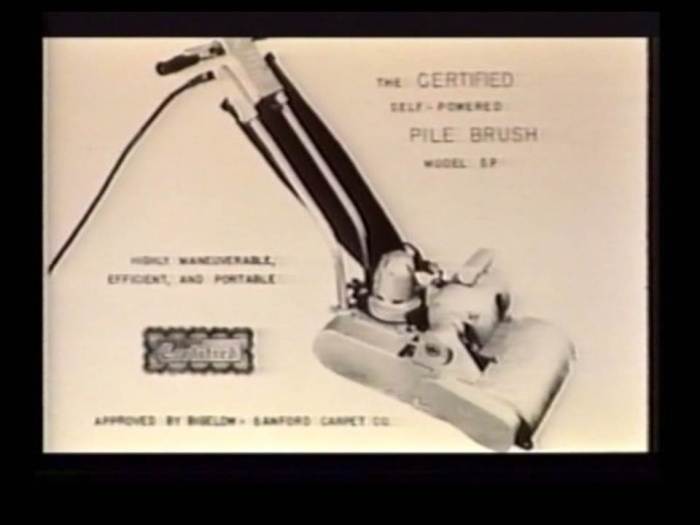

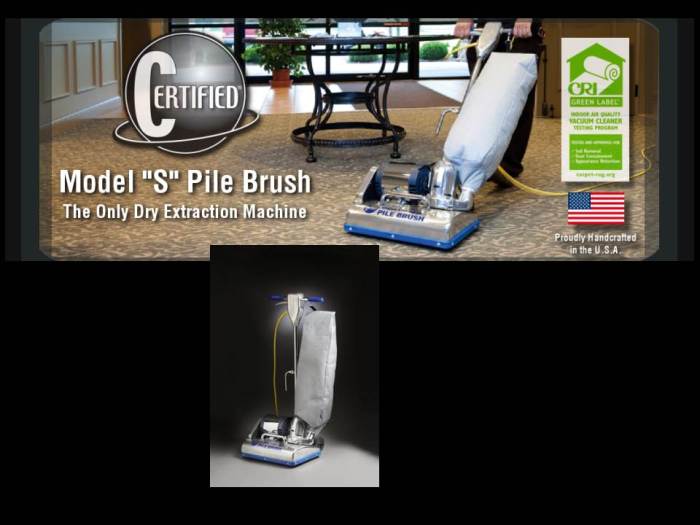

In the 1950’s Certified Equipment introduced the first professional carpet pile lifter. This first pile lifter, pictured here, was made from a converted floor sanding machine. These pictures were provided to Cleanfax Magazine by the founder of Certified, David Burgin. Nilodor, which purchased Certified continues to manufacture an updated version of this Pile Lifter to this day.

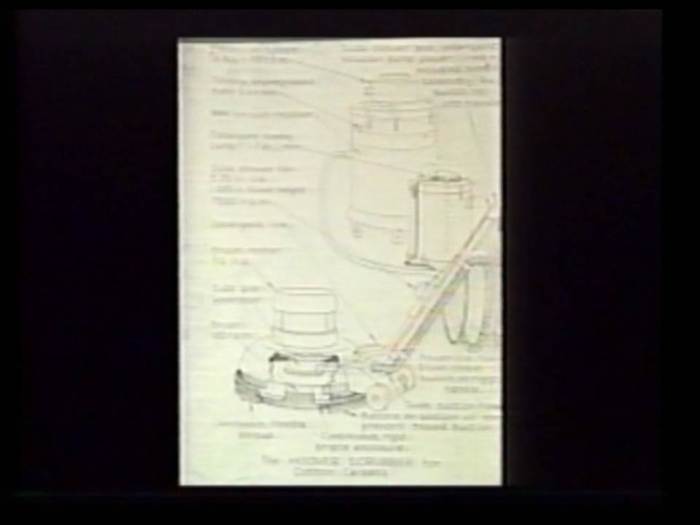

Chemstractor

These drawings represent an idea for a rotary shampoo machine that had extraction capabilities as it applied the shampoo. Although the machine represented in this drawing was never produced, the idea certainly was. Robert “Bob” Hughes was one of the founders of the Chemicals Specialty Company, along with Dan Savanuck. Today, you know the company as Chemspec. Although Chemspec is mainly known for its innovative carpet cleaning chemistry, one important contribution of Mr. Hughes is often overlooked. He developed the Chemstractor, the first rotary floor shampoo machine that also had extraction capabilities. The Chemstractor increased the speed and efficiency of shampooing. The Chemstractor evolved over the years. Perhaps the greatest industry contribution of the Chemstractor and Mr. Hughes was the commercial appearance maintenance management programs and training that was developed. This first brought the concept of interim and restorative carpet cleaning procedures being used in conjunction to develop an on-going maintenance program.

Continue reading at https://historyofprofessionalcarpetcleaning.wordpress.com ...

Host/Racine Industries

From the Host website: “Racine Industries, Inc., manufacturer of the HOST Dry Carpet Cleaning System , began as the Rench Manufacturing Company and was founded by Harry Rench in 1936. From the beginning, Racine Industries, Inc. manufactured carpet cleaning equipment and a dry cleaner. The company was the first in the United States to produce non-resoiling detergents for carpet cleaning, rightfully recognizing that animal based soaps left a residue that contributed to rapid resoiling of the carpet.

In the late 1930s, Rench got involved with the Bigelow Sanford company in a patent pool that resulted in the first dry carpet cleaning powder. This dry ‘powder’ was developed in order to solve a problem that arose when water was used on wool carpet. The solvent-based powder was brushed into the carpet with a broom and vacuumed. The ‘powder’ absorbed the soil and held it until vacuumed out.

In 1956, a new dry cleaner for carpets was introduced at the National Institute of Rug Cleaners in New York. This new product worked better than the original ‘powder’ and could be used with a machine. It was a combination of water, detergents, a safe solvent mixed with ‘sponges’ that dissolved and absorbed the soil under control, and allowed for a thorough extraction at the time of cleaning. It was called HOST Dry Extraction Carpet Cleaner. Over the next 50 years, many innovations were added to the original concept.”

For more information: http://www.hostdry.com/about-host-dry-carpet-cleaning/the-history-of-host

Von Schrader

Although most professional cleaners today know Von Schrader as the leading manufacturer of dry foam carpet cleaning equipment, many may not realize the Von Schrader was certainly one of the first companies to sell running an on-location carpet cleaning business as a way to build a business and a career. According to their web site, “in 1935, in the midst of the Great Depression, an enterprising young man named Francis Von Schrader dreamed of helping people find ways to help themselves. What Fran wanted to sell was not merely carpet cleaning equipment but an opportunity. He believed that if given a chance, industrious individuals could develop and build prosperous, independent businesses.” The company says that since their introduction on the 1930’s, more than 50,000 people have become Von Schrader “Associates.”(Associates are people running their own companies using Von Schrader equipment and programs.)

Von Schrader Upholstery cleaning

Von Schrader introduced what was likely the first professional upholstery only cleaning machine. Using compressed air, it applied a non-resoiling foam to the upholstery fabric that was agitated in with a small rotary brush mechanism.

For more information about Von Schrader, visit their website at ttp://www.vonschrader.com/about-us/our-history

Von Schrader is not the only company that made dry foam shampoo equipment. Advance Machines, now part of Nilfisk manufactured dry foam shampoo application equipment for many years. The first Advance CarpeTron™ dry foam shampooers went into production in 1965.The dry foam method is an effective low moisture, rapid drying carpet cleaning method that has been used in carpet cleaning for decades. The dry foam method is similar to the rotary shampoo method in that brushes are used to agitate the carpet pile. In the dry foam method, an aerator is used to whip the solution in a foam. The foam is dispensed into the horizontally rotating brushes. As with all carpet cleaning methods, the more chemical that is applied, the longer the drying time. Some machines have their own extraction capability. These machines have the capability to remove shampoo and attached soil particles. Other machines do not have extraction capability. A wet/dry vacuum must be used to remove the shampoo and soil.

Bonnet cleaning

Bonnet cleaning has long been one of the most popular carpet cleaning methods, particularly in a commercial carpet setting, and has remained relatively the same since its inception. Bonnet cleaning is a minimum moisture carpet cleaning method. Bonnet cleaning essentially consists of an absorbent cotton, rayon and/or polypropylene pad and an agitation machine. The carpet is generally presprayed with the bonnet cleaning solution, and the cotton, rayon, or polypropylene pad is also moistened with the solution. The pad is attached to the agitation machine. The pad is used to agitate the carpet and to assist in the suspension and absorbance of the soil. Once the pad becomes saturated with soil, it is either rotated to the other side or exchanged for a clean pad. Generally procedures call for post vacuuming once the carpet has dried.

Most bonnet cleaning is done with a rotary floor machine set at a speed of 175rpm. However over the years there have been a wide variety of oscillating and/or orbital agitation machines used with absorbent pads in what could be characterized as bonnet or absorbent cleaning. These pictures were sent to me by John Guerkink of Trinity Carpet Renewal Systems showing a residential cleaning job from 1974 that his father cleaned. Trinity Carpet Renewal Systems utilizes an oscillating agitation rather than rotary.

Other long time bonnet systems have included Argosheen and Ultra-Dry.

Cleaning franchises such as Chem-Dry have, in the past, used variations of the bonnet method with proprietary cleaning solutions over the years. This system today is referred to as the Chem-Dry Legacy System. Many ChemDry Frachises today use a proprietary truckmount hot carbonated solution system.

Many bonnet systems have switched to encapsulation cleaning chemistry utilizing the same agitation machines in the past few years, but with encapsulation chemicals being used instead of traditional bonnet cleaning systems. We will talk more about encapsulation cleaning later.

Rotary shampooing

What do coconuts have to do with professional on-location carpet cleaning?

As on-location professional carpet cleaners began to make their appearance, they began to use a new approach to cleaning carpet. They agitated a bucket of soap and water to form suds and then brushing the suds into the carpet. Coconut oil was the basic ingredient of most detergents at this time that were used to form the suds and toweling with clear water and a touch of ammonia brightened the pile. Later, coconut oil served as the basis for the detergents that were formulated for carpet shampooing utilizing rotary floor machines. The problem with these coconut oil based detergents is that they were sticky and had a tendency to stay in the carpet and act as tacky residue, which could cause the carpet to resoil rapidly after cleaning. This led to the birth of the conception that if you clean you carpets, they will only get dirtier faster. Though coconut oils were replaced by less tacky synthetic detergents in the early 1960’s, the professional cleaning industry to this day has to deal with the misconception usually stated something like this – “Wait as long as you possibly can before you get your carpet cleaned, because once you clean it, it will get dirtier faster.” It does not help that “carpet shampooing” still serves as a generic description for carpet cleaning, even though carpet shampooing has not been the dominant professional on-location carpet cleaning method since the early 1970’s.

In the 1940’s there was not much development in carpet cleaning equipment, chemicals, nor procedures. Much of the world was involved in World War II. Most able bodied men were in the military, and most manufacturing was adapted to meet the needs of military production.

After the war ended, there was an influx of new “talent” into the cleaning business as returning GI’s tried to find a profession. The late 1940’s and early 1950’s were the birthdates of many commercial janitorial companies. “On-Location Professional carpet cleaning in the residential market was still greatly limited to the very wealthy. Through this period, most professional carpet cleaning was done by the rotary shampoo method.

Wet shampoo cleaning with rotary floor machines (175 rpm), involved the application of a foaming detergent into the carpet that was agitated in with a broken in shampoo brush. In most cases, this was followed by thorough wet vacuuming with a wet-dry vacuum. As previously mentioned, these wet shampoos were originally formulated from coconut oil soaps, which meant that the wet shampoo residues would be sticky. Since no rinse or extraction was performed, the powerful residue can continue to collect dirt after cleaning, When wet-shampoo chemistry standards converted from coconut oil soaps to synthetic detergents (usually sodium laurel sulfate) as a base, the shampoos dried to a powder, and loosened dirt would attach to the powder components, requiring vacuuming by the consumer the day after cleaning. The rotary shampoo method remained the most popular way to professionally clean carpet on location until the advent of hot water extraction machines in the 1960’s.

Pile lifter

In the 1950’s Certified Equipment introduced the first professional carpet pile lifter. This first pile lifter, pictured here, was made from a converted floor sanding machine. These pictures were provided to Cleanfax Magazine by the founder of Certified, David Burgin. Nilodor, which purchased Certified continues to manufacture an updated version of this Pile Lifter to this day.

Chemstractor

These drawings represent an idea for a rotary shampoo machine that had extraction capabilities as it applied the shampoo. Although the machine represented in this drawing was never produced, the idea certainly was. Robert “Bob” Hughes was one of the founders of the Chemicals Specialty Company, along with Dan Savanuck. Today, you know the company as Chemspec. Although Chemspec is mainly known for its innovative carpet cleaning chemistry, one important contribution of Mr. Hughes is often overlooked. He developed the Chemstractor, the first rotary floor shampoo machine that also had extraction capabilities. The Chemstractor increased the speed and efficiency of shampooing. The Chemstractor evolved over the years. Perhaps the greatest industry contribution of the Chemstractor and Mr. Hughes was the commercial appearance maintenance management programs and training that was developed. This first brought the concept of interim and restorative carpet cleaning procedures being used in conjunction to develop an on-going maintenance program.

Continue reading at https://historyofprofessionalcarpetcleaning.wordpress.com ...

Last edited by a moderator: