doylebloss

Supportive Member

Professional carpet cleaning has taken on many different looks over the last 115 years. That look has often been molded by the different cleaning methods and equipment, along with the chemistry that has been adapted to clean that carpet successfully. You may or may not recognize some of this equipment and these procedures, but they were all a part of the development of the industry.

If you go to the internet and google “the history of carpet cleaning” what you will find is lots of information about the development of vacuum cleaning equipment since the late 1800’s. Many companies have collected and acquired an impressive array of early vacuums and dusters, including the Museum of Clean hosted by Don Aslett in Pocatello, Idaho. If you ever get a chance to go there, or to see its traveling exhibit that has appeared at the ISSA convention, don’t miss that opportunity.

Our purpose here though is to highlight the development of cleaning equipment and methods used by professional cleaners that go beyond conventional dry soil removal with vacuums. Unfortunately, with many of the earliest innovations, all we have left are the names of people, and the stories of “old-timers” who remember seeing or using that equipment. Not even pictures remain. In my quest to write this blog, there were several early innovators of portable and truckmounted extractors whose contributions can only be mentioned, because an industry wide request could not produce a picture of the machines they made. That difficulty only made me more determined to produce this blog, to make sure that some of the machines that I had pictures of got their story told, and recorded, and digitized, prepared to be preserved and remembered well into the future.

If you are going to talk about carpet cleaning, you almost have to start with a little bit about the history of carpet itself. The Carpet and Rug Institute serves as our resource here. Most of this information comes directly from their website: http://www.carpet-rug.org/About-CRI/History-of-Carpet.aspx

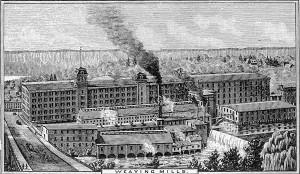

According to the CRI, the carpet industry in the United States began in 1791 when William Sprague started the first woven carpet mill in Philadelphia. Others opened during the early 1800s in New England. Included in that area was Beattie Manufacturing Company in Little Falls, New Jersey, a company that operated until 1979.

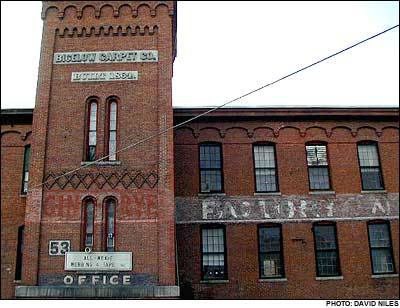

In 1839, Erastus Bigelow permanently reshaped the industry with the invention of the power loom for weaving carpets. Bigelow’s loom doubled carpet production the first year after its creation and tripled it by 1850.

The power loom with Jacquard mechanism was developed in 1849, and Brussels carpet was first manufactured by the Clinton Company of Massachusetts.

Alexander Smith started his carpet manufacturing plant in 1845 in West Farms, New York. An American, Halcyon Skinner, had perfected the power loom for making Royal Axminster in 1876. He and Alexander Smith combined, forming a very successful carpet company. In 1929 Alexander Smith & Sons was the largest manufacturer of carpets and rugs in the world.

Simulating the “Oriental” rug Industrialist/retailer Marshall Field had a traditional Axminster weaving loom modified to create what no one else had ever created — a machine-made rug woven through the back, just like a handmade Oriental, featuring intricate designs and virtually unlimited color variety. Karastan’s rug mill was established in 1926, and introduced the first Karastan rugs to the public in 1928.

The tufted carpet industry: Born in the U.S.A. and the Pride of Georgia

The industry began in a simple way, around the turn of the century. A young, Dalton woman, Catherine Evans Whitener, recreated a bedspread in a hand-crafted pattern she had seen, for a wedding gift.

Copying a quilt pattern, she sewed thick cotton yarns with a running stitch into unbleached muslin, clipped the ends of the yarn so they would fluff out, and finally, washed the spread in hot water to hold the yarns in by shrinking the fabric. Chenille bedspreads became amazingly popular all over the country and provided a new name for Dalton: The Bedspread Capital of the World.

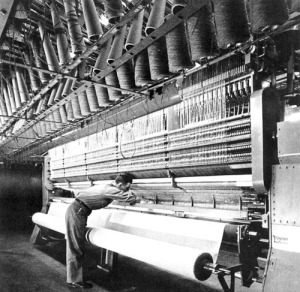

Mechanization—the 1930s Buyer competition, which tended to lower the prices, the change in the minimum wage laws, and development of machine-produced spreads soon made the hand-crafted spreads too expensive. Gradually the industry began to pull the workers from surrounding hillsides and small towns into mills in Dalton, beginning the rapid growth of the mechanized tufting industry.

In the 1930s, as a result of the demand for more bedspreads, the first mechanized tufting machine, attributed to Glen Looper Foundry of Dalton, was developed.

As the number of tufted products produced annually went into the millions, the job of supplying the industry became equally important. Yarn, sheeting, duck mills, and agents were established in the area, with their entire output going to the industry; and larger mills elsewhere vied for the growing business. Machine shops were established to manufacture the thousands of single and multi-needle machines needed, as well as to design improvements aimed at making even more beautiful and better spreads, bathroom sets, robes, beach wear, and rugs. Dye plants for yarn were built. Machinery was developed for making chenille rugs and was widened, creating larger rugs and broadloom carpet. At the same time, machinery was changing; developments of new fibers accelerated the growth of broadloom carpet.

Synthetic fibers are introduced Until about 1954, cotton was virtually the only fiber used in tufted products. Wool and manmade fibers — polyester, nylon, rayon, and acrylics — were gradually introduced by textile men in Dalton. Nylon was first introduced in 1947 and grew steadily to dominate the market. Polyester was first used in 1965 and was followed soon by polypropylene (olefin). Most manufacturers will agree that the single most important development in the industry was the introduction of bulk continuous filament nylon yarns. These yarns provided a luxurious quality, durable carpet, similar to wool, which was more economical to produce. Therefore, a durable, luxury product was offered to the consumer for less money.

In 1950, only 10 percent of all carpet and rug products were tufted, and ninety percent were woven. However, about 1950, it was as if someone had opened a magic trunk. Out of that trunk came man-made fibers, new spinning techniques, new dye equipment, printing processes, tufting equipment, and backing for different end uses. Today, tufted products are more than 90 percent of the total, followed by less than 2 percent that are woven, and 6.7 percent for all other methods, such as knitted, braided, hooked, or needlepunched. Through the years, the Dalton area has continued to be the center of the tufted carpet industry, and today, the area produces more than 70 percent of the total output of the world-wide industry of over $9 billion. Dalton is now known as the “Carpet Capital of the World.”

As you will see, the introduction of synthetic fibers and proliferation of wall to wall, sometimes called broadloom carpets was the main impetus for the development of the on-location professional carpet cleaning industry, and also allowed the development of the cleaning method that would transform the industry – hot water extraction. Though we will see wall to wall carpets that dated back to the late 1890’s, it would not be until 70 years later when it displaced the area rug or oriental rugs as a floor covering of choice.

Continue reading...

If you go to the internet and google “the history of carpet cleaning” what you will find is lots of information about the development of vacuum cleaning equipment since the late 1800’s. Many companies have collected and acquired an impressive array of early vacuums and dusters, including the Museum of Clean hosted by Don Aslett in Pocatello, Idaho. If you ever get a chance to go there, or to see its traveling exhibit that has appeared at the ISSA convention, don’t miss that opportunity.

Our purpose here though is to highlight the development of cleaning equipment and methods used by professional cleaners that go beyond conventional dry soil removal with vacuums. Unfortunately, with many of the earliest innovations, all we have left are the names of people, and the stories of “old-timers” who remember seeing or using that equipment. Not even pictures remain. In my quest to write this blog, there were several early innovators of portable and truckmounted extractors whose contributions can only be mentioned, because an industry wide request could not produce a picture of the machines they made. That difficulty only made me more determined to produce this blog, to make sure that some of the machines that I had pictures of got their story told, and recorded, and digitized, prepared to be preserved and remembered well into the future.

If you are going to talk about carpet cleaning, you almost have to start with a little bit about the history of carpet itself. The Carpet and Rug Institute serves as our resource here. Most of this information comes directly from their website: http://www.carpet-rug.org/About-CRI/History-of-Carpet.aspx

According to the CRI, the carpet industry in the United States began in 1791 when William Sprague started the first woven carpet mill in Philadelphia. Others opened during the early 1800s in New England. Included in that area was Beattie Manufacturing Company in Little Falls, New Jersey, a company that operated until 1979.

In 1839, Erastus Bigelow permanently reshaped the industry with the invention of the power loom for weaving carpets. Bigelow’s loom doubled carpet production the first year after its creation and tripled it by 1850.

The power loom with Jacquard mechanism was developed in 1849, and Brussels carpet was first manufactured by the Clinton Company of Massachusetts.

Alexander Smith started his carpet manufacturing plant in 1845 in West Farms, New York. An American, Halcyon Skinner, had perfected the power loom for making Royal Axminster in 1876. He and Alexander Smith combined, forming a very successful carpet company. In 1929 Alexander Smith & Sons was the largest manufacturer of carpets and rugs in the world.

Simulating the “Oriental” rug Industrialist/retailer Marshall Field had a traditional Axminster weaving loom modified to create what no one else had ever created — a machine-made rug woven through the back, just like a handmade Oriental, featuring intricate designs and virtually unlimited color variety. Karastan’s rug mill was established in 1926, and introduced the first Karastan rugs to the public in 1928.

The tufted carpet industry: Born in the U.S.A. and the Pride of Georgia

The industry began in a simple way, around the turn of the century. A young, Dalton woman, Catherine Evans Whitener, recreated a bedspread in a hand-crafted pattern she had seen, for a wedding gift.

Copying a quilt pattern, she sewed thick cotton yarns with a running stitch into unbleached muslin, clipped the ends of the yarn so they would fluff out, and finally, washed the spread in hot water to hold the yarns in by shrinking the fabric. Chenille bedspreads became amazingly popular all over the country and provided a new name for Dalton: The Bedspread Capital of the World.

Mechanization—the 1930s Buyer competition, which tended to lower the prices, the change in the minimum wage laws, and development of machine-produced spreads soon made the hand-crafted spreads too expensive. Gradually the industry began to pull the workers from surrounding hillsides and small towns into mills in Dalton, beginning the rapid growth of the mechanized tufting industry.

In the 1930s, as a result of the demand for more bedspreads, the first mechanized tufting machine, attributed to Glen Looper Foundry of Dalton, was developed.

As the number of tufted products produced annually went into the millions, the job of supplying the industry became equally important. Yarn, sheeting, duck mills, and agents were established in the area, with their entire output going to the industry; and larger mills elsewhere vied for the growing business. Machine shops were established to manufacture the thousands of single and multi-needle machines needed, as well as to design improvements aimed at making even more beautiful and better spreads, bathroom sets, robes, beach wear, and rugs. Dye plants for yarn were built. Machinery was developed for making chenille rugs and was widened, creating larger rugs and broadloom carpet. At the same time, machinery was changing; developments of new fibers accelerated the growth of broadloom carpet.

Synthetic fibers are introduced Until about 1954, cotton was virtually the only fiber used in tufted products. Wool and manmade fibers — polyester, nylon, rayon, and acrylics — were gradually introduced by textile men in Dalton. Nylon was first introduced in 1947 and grew steadily to dominate the market. Polyester was first used in 1965 and was followed soon by polypropylene (olefin). Most manufacturers will agree that the single most important development in the industry was the introduction of bulk continuous filament nylon yarns. These yarns provided a luxurious quality, durable carpet, similar to wool, which was more economical to produce. Therefore, a durable, luxury product was offered to the consumer for less money.

In 1950, only 10 percent of all carpet and rug products were tufted, and ninety percent were woven. However, about 1950, it was as if someone had opened a magic trunk. Out of that trunk came man-made fibers, new spinning techniques, new dye equipment, printing processes, tufting equipment, and backing for different end uses. Today, tufted products are more than 90 percent of the total, followed by less than 2 percent that are woven, and 6.7 percent for all other methods, such as knitted, braided, hooked, or needlepunched. Through the years, the Dalton area has continued to be the center of the tufted carpet industry, and today, the area produces more than 70 percent of the total output of the world-wide industry of over $9 billion. Dalton is now known as the “Carpet Capital of the World.”

As you will see, the introduction of synthetic fibers and proliferation of wall to wall, sometimes called broadloom carpets was the main impetus for the development of the on-location professional carpet cleaning industry, and also allowed the development of the cleaning method that would transform the industry – hot water extraction. Though we will see wall to wall carpets that dated back to the late 1890’s, it would not be until 70 years later when it displaced the area rug or oriental rugs as a floor covering of choice.

Continue reading...