You need a pressure switch so the pump only runs when it has to. Most RV pumps have them.

My water transfer pump from pond to waterbox on my rigs, get this way after a while. I notice the switch is getting a little crusty too. The transfer pump is constantly running and bypassing when not being demanded.

Is this common?

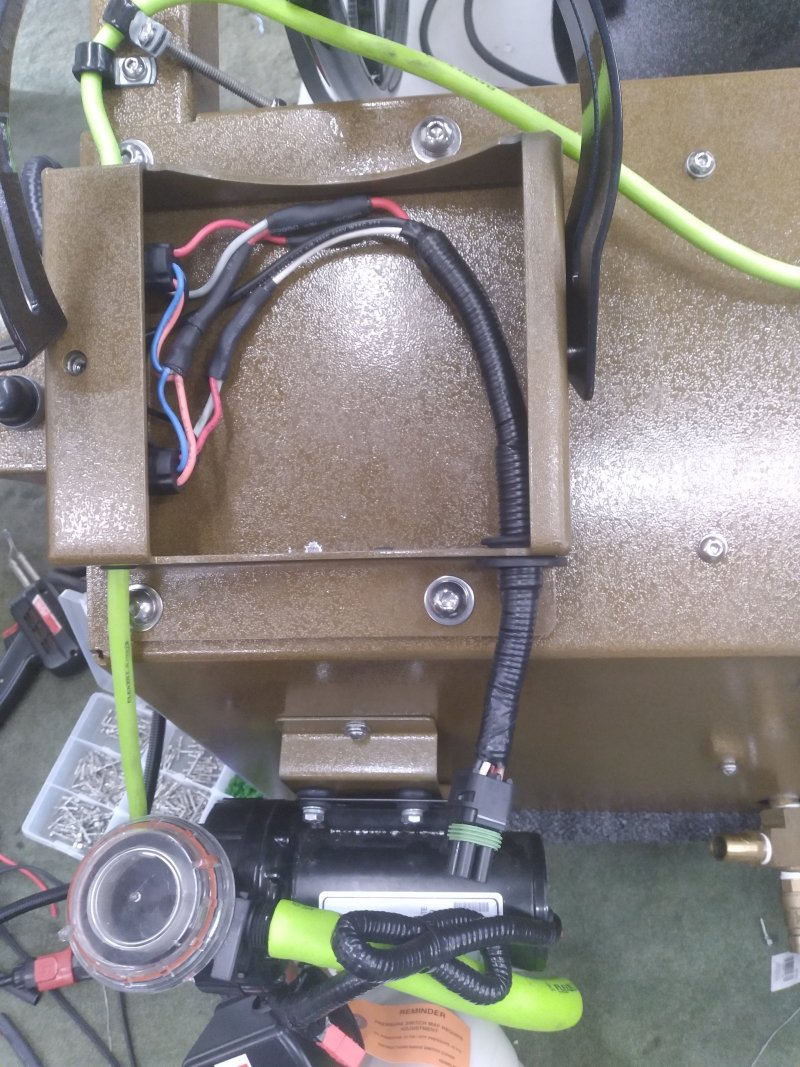

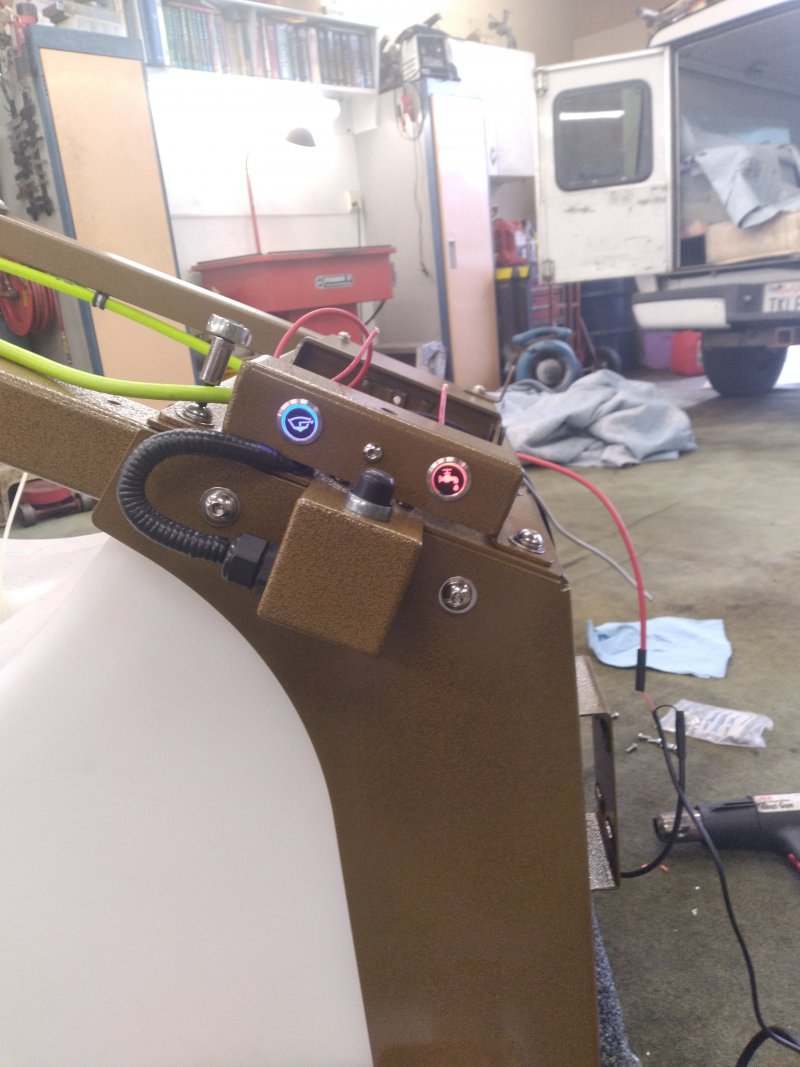

View attachment 121794

View attachment 121795

The wires look a little frayed because it broke when I took the pic so I just have them shoved in there sloppy. It had a clean connection just burnt and the plastic brittle and broken off on the connectors.

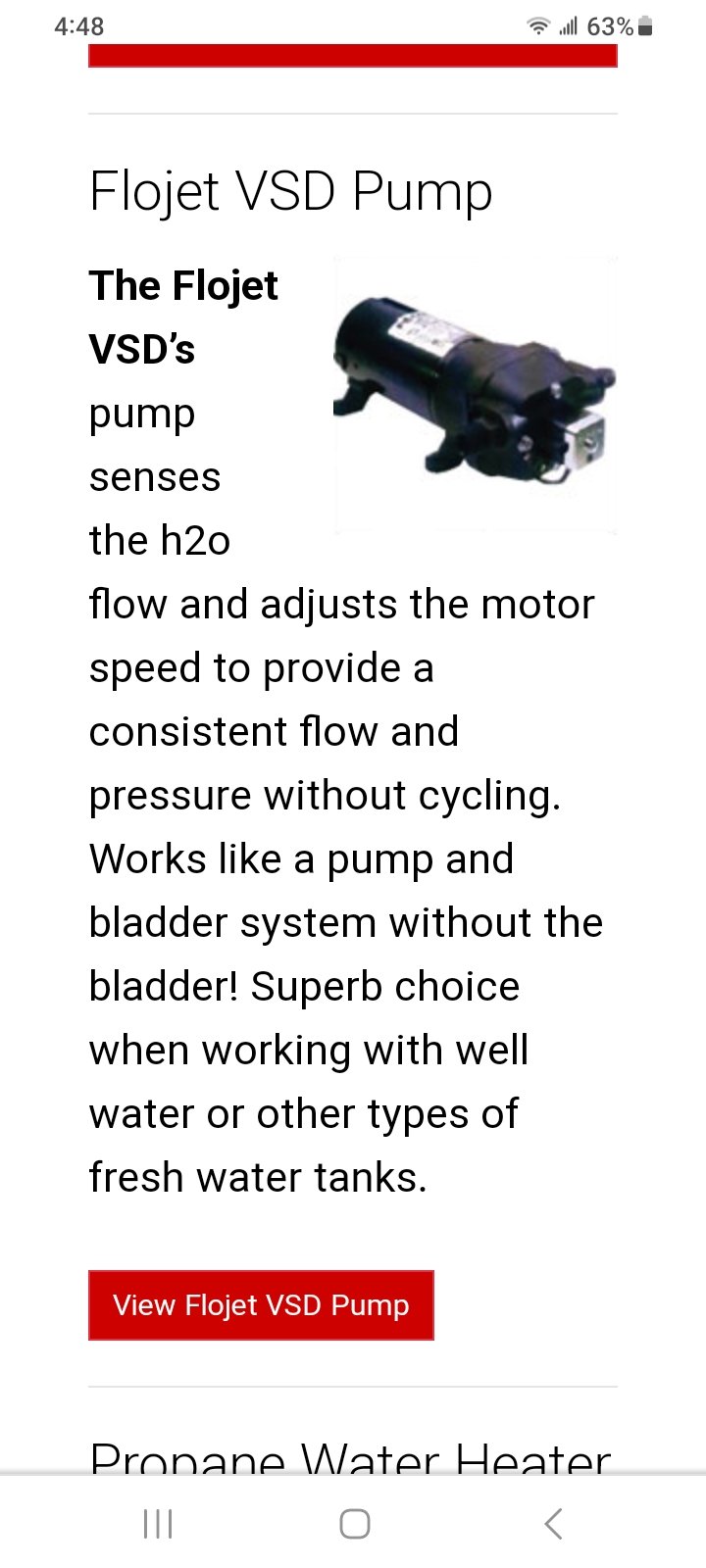

Most Flojet ( Shurflo)transfer pumps have a pressure switch that stops flow where there is no demand; also, the pump is thermally protected; pump stops temporarily after running for a long time to protect itself from burning, the pump runs wet or dry, but sometimes with six hours of continuous run, it'll stop. I'm currently running a 3.3 Gpm flojet pump ( 2-7amps). What brand of transfer pump do you run? Do you have an expansion tank( for even pressure) like Dwain is showing in his pics? What is the pump's gpm? The higher the GPM, the higher the amperage; for example, 4.5 GPM would need up to 20 amps. You need only 35- 45 psi for any transfer pump. There is no way that wires or connectors should be burnt. Check the numbers on your pump( gpm, amps, and psi). How long is the hose running from the transfer pump to the holding tank and hot water tank, if any, respectively to the CAT ( pressure pump), and what is the diameter of the hose( 1/2", 5/8") more loops hose has on the way up, more quietly will enter the tank, so your float switch won't be flapping under a stream of incoming water. Ensure that your quick-disconnect terminals aren't exposed; they are tightly crimped and preferably protected with heat wraps; you can also lift the pump off the floor ( thick styrofoam would do the charm. ). How long are the wires; what is their gauge? The process of elimination is long but necessary. I hope that you'll succeed in finding the source of your problem. I'm hopeful that more guys chip in with their valuable insights.