Hi, my name is Sam Sr. not to be confused with handsome Sam Jr. <img src=pic's

>

>

My son and I have been lurking and stalking the carpet cleans bbs for over a year now and we have ask and gotten prompt and excellent advice. We are mainly a pressure washing contractor but often get ask to cleaning the house on wheel some of the independent truckers have and sometimes the fitly entrance to some of the shops garages and occasionally their homes. We do all kind of flat work and apartments complexes and sometimes we are ask to clean really dirt apartments- they call real carpet cleaners for the not so dirt ones- we have a couple of Mytee 1005s and a rotovac, heat is no problem we have kerosene burners that will heat 10 to 12 gpm even when there’s ice in our tanks.

I’ve been posting lately because Sam was call back to active duty and is back in Iraq. His job is well let’s said to gently interrogate and solicit information from suspected terrorist. Wish him a safe return if you would.

. I was told over a year ago on another board that it would be difficult to build your own tm. They were right although my fist one came out ok I didn’t get to use is but once because it was stolen from the storage unit that assured me that it would be safe there, so I’m at it again trying to put together another unit. I wouldn’t say tm actually because I’m put it on a trailer.

Due to the increasing pressure the EPA is put on waste water we decide to recovery and process almost everything now.

As state above I’m putting another unit and here’s what I’m working with:

1. 65 hp DIESEL ENGINE. <img src=pic's

>

>

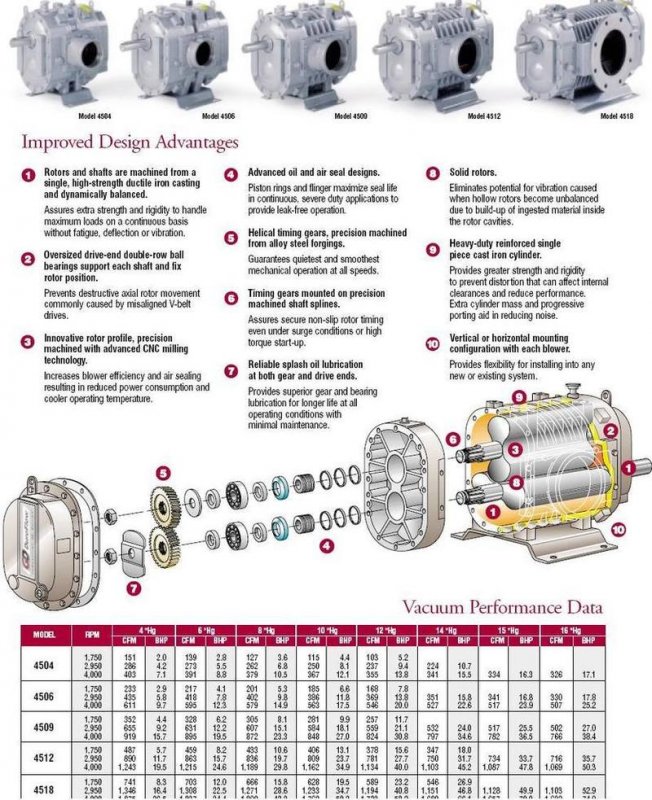

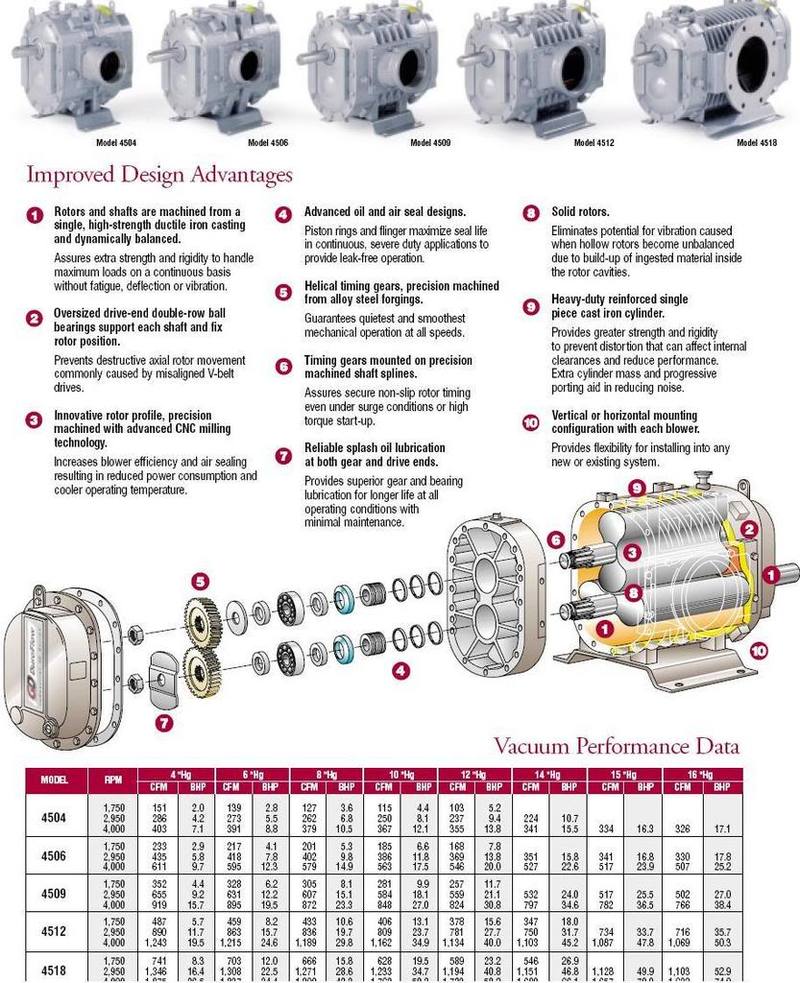

2. 4909 DUROFLOE BLOWER <img src=pic's

>

>

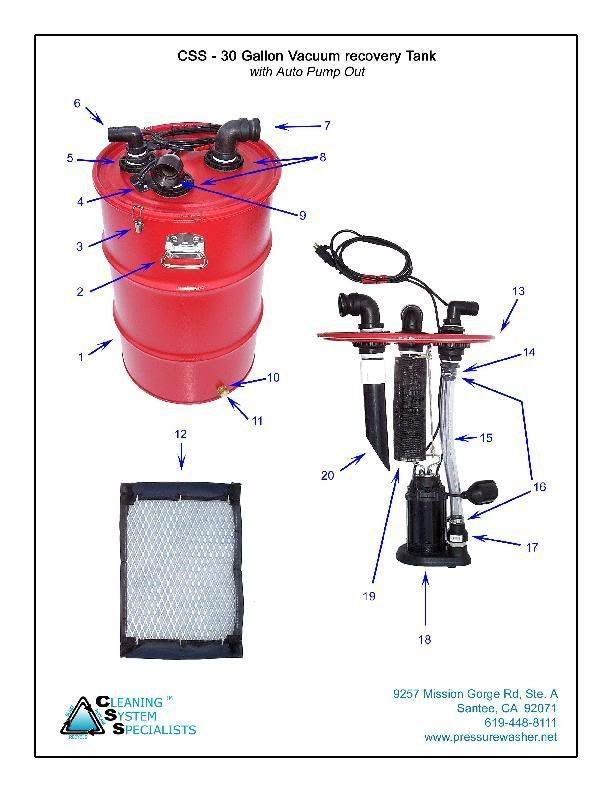

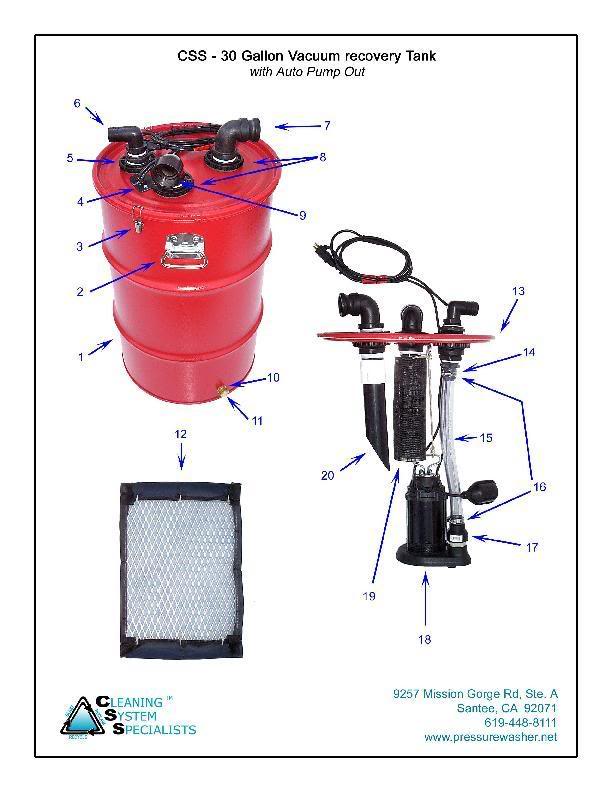

3. 2 30 gal waste tanks <img src=pic's

> ( I have tested these at 18 hg and they work fine)

> ( I have tested these at 18 hg and they work fine)

I will also be purchasing the following:

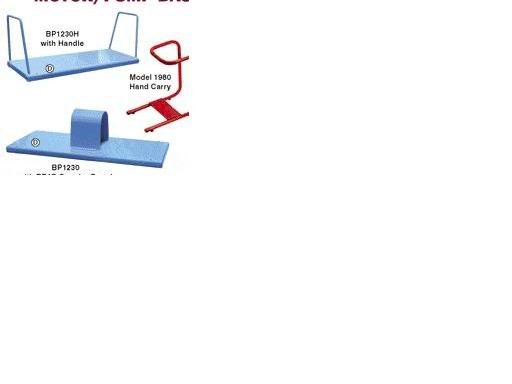

Greenie says that he is going to have some glides and other fixes for the rotovac. I’m going to purchase a high flow wand 3 inch Knuckle and the. Manifold<img src=pic's

> (2.5) and the y (2.5) from him also. . I will split the 5 inch Npt from the blower to the Greenies Manifold <img src=pic's addy > ( two 2.5 ) to two 30 gals waste tanks . Why because I’m hard headed and I have to do it my way.

> (2.5) and the y (2.5) from him also. . I will split the 5 inch Npt from the blower to the Greenies Manifold <img src=pic's addy > ( two 2.5 ) to two 30 gals waste tanks . Why because I’m hard headed and I have to do it my way.

And suggestion will be appreciated

I have more to say but have gone on to long already.

[/url]

My son and I have been lurking and stalking the carpet cleans bbs for over a year now and we have ask and gotten prompt and excellent advice. We are mainly a pressure washing contractor but often get ask to cleaning the house on wheel some of the independent truckers have and sometimes the fitly entrance to some of the shops garages and occasionally their homes. We do all kind of flat work and apartments complexes and sometimes we are ask to clean really dirt apartments- they call real carpet cleaners for the not so dirt ones- we have a couple of Mytee 1005s and a rotovac, heat is no problem we have kerosene burners that will heat 10 to 12 gpm even when there’s ice in our tanks.

I’ve been posting lately because Sam was call back to active duty and is back in Iraq. His job is well let’s said to gently interrogate and solicit information from suspected terrorist. Wish him a safe return if you would.

. I was told over a year ago on another board that it would be difficult to build your own tm. They were right although my fist one came out ok I didn’t get to use is but once because it was stolen from the storage unit that assured me that it would be safe there, so I’m at it again trying to put together another unit. I wouldn’t say tm actually because I’m put it on a trailer.

Due to the increasing pressure the EPA is put on waste water we decide to recovery and process almost everything now.

As state above I’m putting another unit and here’s what I’m working with:

1. 65 hp DIESEL ENGINE. <img src=pic's

2. 4909 DUROFLOE BLOWER <img src=pic's

3. 2 30 gal waste tanks <img src=pic's

I will also be purchasing the following:

Greenie says that he is going to have some glides and other fixes for the rotovac. I’m going to purchase a high flow wand 3 inch Knuckle and the. Manifold<img src=pic's

And suggestion will be appreciated

I have more to say but have gone on to long already.

[/url]