You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4.8 CDS RPM

- Thread starter Jayson

- Start date

TimP

Member

- Joined

- May 19, 2007

- Messages

- 4,055

Greenie what size pipe do they run to the tank? Do they go from 3" - 2.5"?

Jim Martin

Supportive Member

according to my book

the 4005 model is 3600 rpm

and the 4007 model is 3600 rpm

the 4005 model is 3600 rpm

and the 4007 model is 3600 rpm

Studebaker

Member

I will make a call Monday. I know the engineers well. We have the 4.8 also.

Hmm. They finished the install today and as far as I can tell the piping from the blower to recovery tank is 3" with nice smooth bends.

I had them tweek my set up a little bit. I'm running 2" all the way up to a 1 3/4" Hydasonic wand with a green glide on it. I had them ditch the hydraho wand...yuck. I got a SMOKING deal on the hydrasonic and green glide combo. It was lightly used and we paid about the same as any decent big tube 4 jet wand out there.

The HG is set at 14" but there is small issue with the fast idle. I'm only getting 1250-1300 rpm. They had to order a new RPM sensor thingy, there are pre set and I must of got one that was a little off.

I'm going to play with it this weekend a lil bit and test out all the cool little features and get use to the machine.

It's got the "salsa" option, auto pump out, blue line fresh water tank with the molded in electric vac reel, got a 3 tier stainless shelving, stainless hydro force holder, stainless double pump up holder, block and tab holder.

It's installed a extended 08 E350. Looks like I'll be able to fix it 2 CVX airmovers, 2 Evo dehus and 6 sahara airmovers for those little floods that come to me when our big rigs are all tied up.

I had them tweek my set up a little bit. I'm running 2" all the way up to a 1 3/4" Hydasonic wand with a green glide on it. I had them ditch the hydraho wand...yuck. I got a SMOKING deal on the hydrasonic and green glide combo. It was lightly used and we paid about the same as any decent big tube 4 jet wand out there.

The HG is set at 14" but there is small issue with the fast idle. I'm only getting 1250-1300 rpm. They had to order a new RPM sensor thingy, there are pre set and I must of got one that was a little off.

I'm going to play with it this weekend a lil bit and test out all the cool little features and get use to the machine.

It's got the "salsa" option, auto pump out, blue line fresh water tank with the molded in electric vac reel, got a 3 tier stainless shelving, stainless hydro force holder, stainless double pump up holder, block and tab holder.

It's installed a extended 08 E350. Looks like I'll be able to fix it 2 CVX airmovers, 2 Evo dehus and 6 sahara airmovers for those little floods that come to me when our big rigs are all tied up.

Jim Martin

Supportive Member

TimP said:Greenie what size pipe do they run to the tank? Do they go from 3" - 2.5"?

my book shows it to be all 3 inch to the tank............

Jim Martin

Supportive Member

that is what the book says.what HM has it set for you have to ask them

Jim Martin

Supportive Member

mine had the salsa.........

Jim Martin

Supportive Member

the 4.6 like in the picture

runs to the end

and the 4.8 runs to the center

I had the 4.8

I just put up the 4.6

the 3 inch is the same

runs to the end

and the 4.8 runs to the center

I had the 4.8

I just put up the 4.6

the 3 inch is the same

Jim Martin

Supportive Member

4.8

Dolly Llama

Number 5

If you notice, that says "max operating limits" .

Not what it's set up to run at

..L.T.A.

Not what it's set up to run at

..L.T.A.

Dom Agostino

Member

- Joined

- Mar 18, 2007

- Messages

- 35

14" is more likely, they don't recommend anything above that, I HAD a 4.8

My new 4.8 has the 3" hose running to the back of the tank to the relief like the 4.6 in the picture.Greenie said:Hmm......So what year did they move the blower intake and relief valve from the end to the center of the tank?

Oh wait...you had the 4.6

Gotcha.

It had the 4005 blower with intake on the end of the tank.

Just did some rough measurements of the pulley set up for the blower. Looks like it may be spinning around 2,400rpms.....MAX if I measured right. Does not sound right to me. At those rpms that blower is only moving the CFMs of a 3.3 @ 3,400.

Of course this all assumes that drive shaft is turning at 1500 rpms matching the crank rpms of the engine. Now if it's spinning the shaft faster than 1,500 rpms than everyting now changes.

I'd lay money down on it that AT BEST it's turning 3,000 rpms if it's lucky. They say 25% more Vacuum at a lower engine RPM over the older 4.8s. I beleive the old one spun @ 2,400 rpms as well as the engine did.

mine is set @ 14hg.Dom Agostino said:14" is more likely, they don't recommend anything above that, I HAD a 4.8

Valid point...but no. I assumed the driveshaft off the engine matched the RPM of the Crank, seeing as how the rpm gauge in the dash matches the RPMS on the display on the hydramaster...but that may mean squat to the actual rpms it's turning.Rex Tyus said:Did you calculate the fly wheel variation as well as the pulleys on the machine?

So I went to tuthills web site for more data. IF the 4007 blower is running @ 2,500rpms, Max lift is 14hg and about 300CFM on there standered 4007 competitor plus blower. I think the one one the CDS has some tweaks to along with being a trilobe.

My vac is going to be piss poor in comparison to my EZ spinning that 4007 @ 3,400 rpms. Granted, tank design, inlets and outlets all play a crucial roll in air flow.

First thing I'm doing to putting a stainless Y to the 2 2" vac ports on that recover tank. Those 90* bends just kill me. using both of them should net me a few more CFMs.

Steve Smith

Member

- Joined

- Nov 15, 2006

- Messages

- 176

Tri-lobe blowers general produce slightly less cfm than a same sized bi-lobe blower spinning at the same rpm.

Maybe you can change your pulley size to spin your blower faster.

Maybe you can change your pulley size to spin your blower faster.

Valid point...but no. I assumed the driveshaft off the engine matched the RPM of the Crank, seeing as how the rpm gauge in the dash matches the RPMS on the display on the hydramaster...but that may mean squat to the actual rpms it's turning.

I don't know much about the Hydramaster. Often on Clutch drive systems the clutch is a smaller diameter than the fly wheel. Easy to under state the rpms of the blower in that case.

TimP

Member

- Joined

- May 19, 2007

- Messages

- 4,055

I've set my truck to run a bit faster close to 1600 max that hydramaster allows. And I let my blower get up to right at 15 hg. As for the new idle booster it is adjustable and doesn't come from the factory pre set. You need a flat head tiny screw driver eyeglasses size to adjust it. My blower tube runs straight into the tank and has a smaller looking water box than what is shown in the picture, above it. Mine has the 4.8 salsa system too. The reason I asked about the size of pipe was because I wanted to see about being able to use 2.5 inch hose. It seems that if we can figure out w hat the blower is being spun at we could increase it either by fly wheel or increasing the rpms to get more air flow out of is so that running 2.5 hose would be worth doing?

TimP

Member

- Joined

- May 19, 2007

- Messages

- 4,055

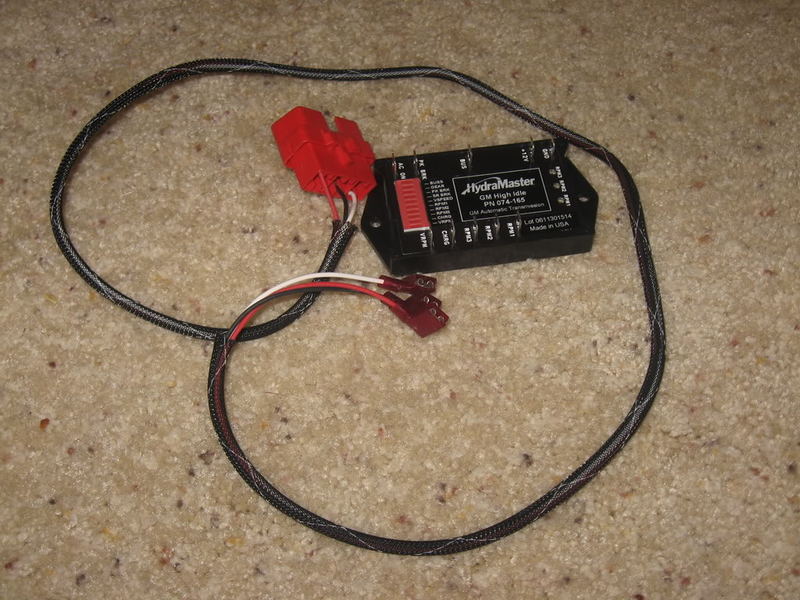

Here is a picture of it

On the top there are 3 holes that say rpm 1 rpm 2 rpm 3. you just turn the screw about a half turn or a quarter turn at a time till you get the right rpm you need.

On the top there are 3 holes that say rpm 1 rpm 2 rpm 3. you just turn the screw about a half turn or a quarter turn at a time till you get the right rpm you need.

The above picture is an Off Road Engineering product. Rpm's are adjusted using a small flathead screwdriver (like a jewelers screwdriver). On the right hand side you see 3 small screws for rpm adjustment. I really Really wouldn't suggest running your new GM or Ford van over 1600 rpm. There's way too much heat created under the hood and you can ruin a catalytic converter fast. These manufacturers are now offering 100 K mile/5 year warranties and GM even has an optional 250K mile warranty. They're doing this to compete in the marketplace but don't think for a second they won't scrutinize every aspect of How the van was being used before honoring any warranty work. This costs them big money and profits are low in Detroit as it is. A guy comes in with a blown headgasket, a fried wiring harness, a ruined converter or a host of other issues and who do you think the blame will fall upon? Keep the engine rpm in the low-midrange (1200-1500) setting and you'll have acceptable under hood temperatures as well as a cool running engine that will last a long time. So then, how does one increase the blower speed? First, can your drivetrain handle it? If so, is the wastetank, filtering and silencing system designed to accommodate your wishes? If the answer is yes then you simply have an issue of pulley ratios. In general, the bigger the pulley the better. There's simply more surface area for the belt to grip to. For example, the Driveshaft pulley on my machine is 8 inches in diameter. If I had a 1 to 1 ratio on the engine/shaft speed, and the engine was running at the max speed of 1500rpm, I could in theory run the blower at 3000 rpm if I were to put a 4 inch pulley on the blower. However, the surface area for the belt to grip a 4 inch pulley is maybe 1.5" when the machine is in use. That's ok if you like changing your belts every week. For a Reliable system I've found a 5 1/4" blower pulley to be about the minimum size diameter for a well rounded belt drive system. Larger would be better but you'll sacrifice blower speed. It's all about balance. Some guys might try and tighten the belts as much as they can to get them to hold. That's great for a little while until you have bearing failures from too much side load pressure. Take it for what it is... A simple, reliable space saving unit. If everything is plumbed right and all aspects of the unit are well balanced you'll have excellent single wand power. All machines have their place. Big diesel pto's, small entry level slide ins, shaft drives.. It just depends on your needs. If a guy needs more then he'd be best off buying more..