Water Rinse Extraction aka Hot Water Extraction aka Steam Cleaning. I use WRE to be general, regardless of heat. Water is the extraction media. I just don't want to list them all.WRE?

What's that?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fast Foamer info

- Thread starter Mikey P

- Start date

Russ Roberts

Member

- Joined

- Oct 28, 2015

- Messages

- 5

- Name

- Russell Roberts

Practically the same meaning, unless you're looking under a microscope, and even then you'd have very little to go off of, you would have little difference in who cleaned what, maybe Steve can post the findings, I don't have them.Can you explain what "practically the same" is based on?

Ease of use?

Time spent ?

ATP testing?

Dry time?

Or just visual appearance?

How about corners, edges, under furniture, narrow areas, stair risers and bullnoses?

Heavy grease?

Urine?

You know, all the same areas and situations that present challenges for all vlm methods ..

Thanks for chiming in!

Ease of Use?

Just like a CRB now but with , however you have two extra connections (combined into a thick "cord") and you don't need someone to spray for you, just fill up the attached tank (up to 20 gallons) and go.

Time Spent?

Yeah you have to fill a tank with water and mix some chems but you'd have to do that anyway, but you don't have to stop to spray, or pump a sprayer, you just go. Cleaning production is 2000+ sq ft an hour. If its not dirty you can really crank out some sq ft.

ATP testing? No clue I don't have any of the data.

Dry Time? Same as regular encap, or faster it is foam after all.

Or just visual appearance? Not sure what you meant by this.

It has the same limitations as a regular CRB on corners, edges, furniture, narrow areas, stairs, etc as a normal CRB.

Like other encaps, grease is the limitation, this also isn't for residential this is for commercial, and not the grease trap restaurants no one wants to clean as I previously said.

Encaps don't touch urine anyway, extract it, and this isn't made for residential, this is for commercial.

To answer the question about the blue brushes, yes that's the preferred brushes according to the CRI and the carpet mills so you don't void warranties due to the higher denier (stiffness) of the other brushes distorting the pile.

Apologies for delays. I don't do social media or post much.Can you explain what "practically the same" is based on?

Ease of use?

Time spent ?

ATP testing?

Dry time?

Or just visual appearance?

How about corners, edges, under furniture, narrow areas, stair risers and bullnoses?

Heavy grease?

Urine?

You know, all the same areas and situations that present challenges for all vlm methods ..

Thanks for chiming in!Apologies for the delay. I don't do social media or post much.

This is a lot and we'll get to it eventually. The Fast Foamer does not replace WRE when it come to urine, heavy organics, etc. this is primarily for the majority of commercial built environments where WRE systems are not applicable to the majority of the environment. The 85%/ 15% soil matrix. There is a place for every method. If the entire space can be cleaned via encapsulation extraction while in front of the restrooms and break room may require WRE, either periodically during a planned maintenance program or a single cleaning intervention. We don't need to WRE the entire space. This is technically "wrong" in the sense of overkill, inefficiency.

I won't get into "deep cleaning" yet, but water penetration is not "deep cleaning". I'll share what "deep cleaning" is, which is for "health" soon. But I have "depth of the pile" and "comprehensive" covered as well."Deep cleaning" is part of the WRE corruption bias. It was most likely added because of the asthma & allergy scare the industry went through in the 90's & 2000's and why it was introduced in the S100 2011 revision. WRE bias got their way. Yes, we knew better at the time. So, why did they really add it?

Look at the composition of the S100 over the years and who shaped it? Bill Bane, Jeff Bishop and others. BIAS! Not hating, I get why they did what they did. However, this has to be rectified or the liability must shifted to the IICRC, CRI and manufacturer's.

Playtime is over. The reckoning is here. How painful the industry wants it to be is on them.

I can't tell you all my secrets because I've expanded on the "science of cleaning" and re-written the principle of cleaning to be "principles of soil removal" to encompass dry compound and encapsulation extraction. These are complete extraction/ cleaning methods. As well as created a new system that cannot be corrupted.

It's based on physics (movement) over chemistry, chemistry (preparation) and extraction interventions.

When we say the Fast Foamer often rivals if not exceeds WRE, we're not talking restaurants, dissolving, emulsification, etc. We are talking about environments like office, retail, hospitality, etc. where if one is vacuumed and WRE vs vacuumed and the Fast Foamer is used. The Fast Foamer will outperform WRE, particularly if a CRB is not used.

The Fast Foamer isn't trying to replace WRE or the Truckmount systems. It's about proper product care, getting rid of prohibited ineffective and inefficient rotary type systems, which has been deemed bad since the 1980's. Yet, oscillation was introduced.

I don't want to break anyone. This is a lot of info to take in and it's not really far off of what we already know. However, it's still a lot when you wake people up. They get ornery, LOL!

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

can you clarify what WRE stand for?Apologies for delays. I don't do social media or post much.

This is a lot and we'll get to it eventually. The Fast Foamer does not replace WRE when it come to urine, heavy organics, etc. this is primarily for the majority of commercial built environments where WRE systems are not applicable to the majority of the environment. The 85%/ 15% soil matrix. There is a place for every method. If the entire space can be cleaned via encapsulation extraction while in front of the restrooms and break room may require WRE, either periodically during a planned maintenance program or a single cleaning intervention. We don't need to WRE the entire space. This is technically "wrong" in the sense of overkill, inefficiency.

I won't get into "deep cleaning" yet, but water penetration is not "deep cleaning". I'll share what "deep cleaning" is, which is for "health" soon. But I have "depth of the pile" and "comprehensive" covered as well."Deep cleaning" is part of the WRE corruption bias. It was most likely added because of the asthma & allergy scare the industry went through in the 90's & 2000's and why it was introduced in the S100 2011 revision. WRE bias got their way. Yes, we knew better at the time. So, why did they really add it?

Look at the composition of the S100 over the years and who shaped it? Bill Bane, Jeff Bishop and others. BIAS! Not hating, I get why they did what they did. However, this has to be rectified or the liability must shifted to the IICRC, CRI and manufacturer's.

Playtime is over. The reckoning is here. How painful the industry wants it to be is on them.

I can't tell you all my secrets because I've expanded on the "science of cleaning" and re-written the principle of cleaning to be "principles of soil removal" to encompass dry compound and encapsulation extraction. These are complete extraction/ cleaning methods. As well as created a new system that cannot be corrupted.

It's based on physics (movement) over chemistry, chemistry (preparation) and extraction interventions.

When we say the Fast Foamer often rivals if not exceeds WRE, we're not talking restaurants, dissolving, emulsification, etc. We are talking about environments like office, retail, hospitality, etc. where if one is vacuumed and WRE vs vacuumed and the Fast Foamer is used. The Fast Foamer will outperform WRE, particularly if a CRB is not used.

The Fast Foamer isn't trying to replace WRE or the Truckmount systems. It's about proper product care, getting rid of prohibited ineffective and inefficient rotary type systems, which has been deemed bad since the 1980's. Yet, oscillation was introduced.As well as restoring balance to the industry.

I don't want to break anyone. This is a lot of info to take in and it's not really far off of what we already know. However, it's still a lot when you wake people up. They get ornery, LOL!

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

The S100 under it's last revision 5 years ago, added lots of VLM content, which I was a part of.

they just started revising it again, so I'd expect a bit more.

Expectations? If you're anything like me. You'll be disappointed. I'm a non-voting member on the S100, while Daryl Hagan (CRI) has the lead chair and Richard Bodo is co-chair. These guys don't know cleaning. Daryl is part of the "old guard" and Bodo is a "gate keeper". We know why they were chosen.The S100 under it's last revision 5 years ago, added lots of VLM content, which I was a part of.

they just started revising it again, so I'd expect a bit more.

The first production had a heavy, bulky external compressor but has since been replaced with a proprietary smaller continuous run compressor simplifying things. If I had to choose a Fast Foamer with the heavy, bulky compressor, I'd still take it, opposed to no Fast Foamer at all. Plus, the 50 -100 models with the external compressor can be retrofitted with the newer proprietary smaller internal compressor.I watched your videos, I see you use an air compressor. Very interesting.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

you really should consider joining us at mikeysfest where many Industry super starrs will be seeing your methind for the first time, including the IICRC staff

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,230

- Name

- Ron Marriott

Not a fan of the knob control for the foam. I would prefer a trigger or a lever of some sort.

I thought this too, but it's too fatiguing. Plus, a solenoid would need to added only increasing parts that can fail. The ball valve is the way to go. The onboard trigger sprayer is not for "advanced encapsulation extraction", those are for "pile lifting" aka "traditional encapsulation extraction" the Whittaker blow and go method is what I like to call it. No dwell and minimal agitation. Which to this day, Whittaker still stays single and dual pass. Not that it can't be used. Use what makes you the most effective and efficient and applicable to the cleaning objective. I just wanted to explain because these are all questions I had and still want to try. If I get a solenoid version demo worked up to test I'll share.Not a fan of the knob control for the foam. I would prefer a trigger or a lever of some sort.

I'd like a tether that kills the foam (closes the ball valve) because I sometimes walk away with the foam on, LOL. Like a kill switch on a Sea-doo. It's not a bid deal but to see the CRB surround by a big plum of foam makes you want to panic and spread it around real quick but the foam is so dry, it's really not that much moisture.

icleancarpetz

Member

- Joined

- Mar 7, 2015

- Messages

- 1,703

- Name

- Rafael Samson

Releasit creates a foam.I'm curious as to how the system produces foam. The Von Schrader system utilizes the vacuum motor exhaust to aerate the foam, blowing a very dry foam out of the machine where is is scrubbed in by the cylindrical brush then vacuumed up.

Releasit creates a foam.

Not all foams are created equal.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

I just want to know what WRE stands for......

Kenny Hayes

Member

- Joined

- Apr 17, 2009

- Messages

- 10,032

- Name

- Kenny Hayes

Ooh, ooh, I know  he said!

he said!

Last edited:

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,230

- Name

- Ron Marriott

Most Encaps can be foamy but not the same as an aerated foam. It's much drier.Releasit creates a foam.

Russ Roberts

Member

- Joined

- Oct 28, 2015

- Messages

- 5

- Name

- Russell Roberts

Water Rinse Extraction aka Hot Water Extraction aka Steam Cleaning. I use WRE to be general, regardless of heat. Water is the extraction media. I just don't want to list them all.I just want to know what WRE stands for......

Steve answered your question you just didn't see it.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

Water Rinse Extraction aka Hot Water Extraction aka Steam Cleaning. I use WRE to be general, regardless of heat. Water is the extraction media. I just don't want to list them all.

Steve answered your question you just didn't see it.

40+ years, never heard it acronym'd that way..

icleancarpetz

Member

- Joined

- Mar 7, 2015

- Messages

- 1,703

- Name

- Rafael Samson

I dont think the commercial client cares one bit about how drier or faster your cleaning method dries. It will be dry by the time the office opens in the morning. Whittaker CRB Orbot Cimax, hell 175 swing machine all with a good encap, vacuum before and after….same sheet. Brilliant results in the hands of a good operator.Most Encaps can be foamy but not the same as an aerated foam. It's much drier.

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,230

- Name

- Ron Marriott

When you are doing highrise hallways, faster drying is always good. I prefer to be done an hour before kids are getting out of school or people getting home from work. Most of what I do dries in about an hour.I dont think the commercial client cares one bit about how drier or faster your cleaning method dries. It will be dry by the time the office opens in the morning. Whittaker CRB Orbot Cimax, hell 175 swing machine all with a good encap, vacuum before and after….same sheet. Brilliant results in the hands of a good operator.

icleancarpetz

Member

- Joined

- Mar 7, 2015

- Messages

- 1,703

- Name

- Rafael Samson

There you go. If aint broke….When you are doing highrise hallways, faster drying is always good. I prefer to be done an hour before kids are getting out of school or people getting home from work. Most of what I do dries in about an hour.

Kenny Hayes

Member

- Joined

- Apr 17, 2009

- Messages

- 10,032

- Name

- Kenny Hayes

Same with assisted living centers. If you can clean those without soaking the carpet, you’re aces. If they can walk on it while it’s damp, even better.

Sierra Clean Care

Member

- Joined

- Jun 20, 2016

- Messages

- 6,563

- Name

- Jeff T

We did 14,950 sqft of a LARGE, open conference room on Monday.

There must have been 1000 food and drink spills over the vast space.

I’m always open, and looking for new, and innovative ways to improve my system…

Fast foamer would not work in this application.

The hose run from loading dock to the end of the giant room was 275’.

I ran 200’ of 2.5, and a 75’ whip of 2”. Suction was amazing, the wool carpet was only 6 months old, and shed like a long haired cat in the spring time.

We vacuumed for 2 hours with 2 ‘Powered lift away’ Shark vacuums, , and emptied every 15-20 minutes.

, and emptied every 15-20 minutes.

I applied my cleaner (wool safe), through a Cimex with beige pads.

During extraction, I checked my waste tank every hour. After the second hour, I pulled my drop basket…

After the job, once back at the shop, I ran a filter.

We got 2, 5 gallon pails of wool fibre out. I’d estimate it to be approximately 3-4 sweaters worth.

There’s no easy way to remove the funk, and produce an above satisfactory result without actually REMOVING it…

I’d be interested in seeing how it performs in other commercial applications however.

There must have been 1000 food and drink spills over the vast space.

I’m always open, and looking for new, and innovative ways to improve my system…

Fast foamer would not work in this application.

The hose run from loading dock to the end of the giant room was 275’.

I ran 200’ of 2.5, and a 75’ whip of 2”. Suction was amazing, the wool carpet was only 6 months old, and shed like a long haired cat in the spring time.

We vacuumed for 2 hours with 2 ‘Powered lift away’ Shark vacuums,

I applied my cleaner (wool safe), through a Cimex with beige pads.

During extraction, I checked my waste tank every hour. After the second hour, I pulled my drop basket…

After the job, once back at the shop, I ran a filter.

We got 2, 5 gallon pails of wool fibre out. I’d estimate it to be approximately 3-4 sweaters worth.

There’s no easy way to remove the funk, and produce an above satisfactory result without actually REMOVING it…

I’d be interested in seeing how it performs in other commercial applications however.

"water rinse extraction - A method of cleaning in which, following dry soil removal, a liquid cleaning solution is applied and then manually or mechanically agitated throughout the carpet pile. After an appropriate dwell time, suspended soils are rinsed under pressure with a hot or cold water-based solution (with frequently-used areas being rinsed at least twice), and extracted via wet vacuums. Carpet pile is then groomed and dried as necessary".40+ years, never heard it acronym'd that way..

I know this is a power play and I like to have fun too! However, this is not why I'm here. Why say, Hot Water Extraction (HWE) instead of "Steam Cleaning"? Why do some use "Steam" while others use "Hot Water"?

Again, I'm not trying to goat you. We know "Steam" was challenged and why we got HWE and when it comes to WRE, we have plenty of thermal energy with 60-75 degree water as it relates to the Kelvin scale. Thermal, temp, heat is relavent to "compacted soiling" aka heavy organics, aka dry-solvent solubles yada yada. I know more about methods and how they work than most.

It's like "Steam". I'm sure one of your stewards has the definition given to Bane from a DuPont chemist. That's when we start talking about cleaning. Otherwise, we're just sharing opinions. Science overall! I like you Mikey P! We're going to be good friends.

Please don't! This is not going to end well for you. Let's break this down. You have no experience with the Fast Foamer and no idea how it works and if it would be applicable as you are obviously not qualified to be speaking on this. I'm not here to destroy, but understand how I work. I will come at you with peace and willing to share all my knowledge to you or anyone who wishes to better themselves and the industry. Before I start. When I say "wrong", it's not 100% wrong because you have not been taught properly. I was taught properly and it still took me years to master it. So, I'm not attacking you. Even I can be "wrong". There is "wrong" as in appropriate, proper and adequate. "Wrong" as ineffective or inefficient.We did 14,950 sqft of a LARGE, open conference room on Monday.

There must have been 1000 food and drink spills over the vast space.

I’m always open, and looking for new, and innovative ways to improve my system…

Fast foamer would not work in this application.

The hose run from loading dock to the end of the giant room was 275’.

I ran 200’ of 2.5, and a 75’ whip of 2”. Suction was amazing, the wool carpet was only 6 months old, and shed like a long haired cat in the spring time.

We vacuumed for 2 hours with 2 ‘Powered lift away’ Shark vacuums,, and emptied every 15-20 minutes.

I applied my cleaner (wool safe), through a Cimex with beige pads.

During extraction, I checked my waste tank every hour. After the second hour, I pulled my drop basket…

After the job, once back at the shop, I ran a filter.

We got 2, 5 gallon pails of wool fibre out. I’d estimate it to be approximately 3-4 sweaters worth.

There’s no easy way to remove the funk, and produce an above satisfactory result without actually REMOVING it…

I’d be interested in seeing how it performs in other commercial applications however.

1. Vacuuming. There is no reason to use a vacuum that aggressively on a wool carpet. Regardless of your perceived soil load. The vacuum isn't supposed to work on mechanical agitation. Yes, there is some, however it works by using two unique air flows. One created by the brush roll spinning at about 4k RPM. This RPM creates a vibration that separates the micro particulate 10 microns or less, typically about 2.5 microns which are primarily responsible for make carpet look "dirty". Couple that with a soluble aka binding agent aka the "sticky stuff". The brush roll creates a low pressure zone that pulls these micro particulate separating it from the fiber, suspending and "entraining" it into another low pressure air flow created by the vac motor. It's called "entrainment". Get use to that word because I've expanded on the science of cleaning particularly leading with physics fluids and the introduction of "mechanical entrainment" which creates an "Entrainment Trifecta" AIR (vacuuming) > MECHANICAL (CRB MACHINE, the brushes act as a QUASI-FLUID) > WATER (water rinse extraction). Vacuuming isn't "dry soil removal", it is "loose dry soil removal", Oh! I guess the cat is out of the bag, I've revised the principles, well not revised, expanded really and created the "principles of soil removal" for commercial textile floor coverings.

2. Regarding Cimex. This is where you done ****** up! I'm not even going to speak on this as it is insanity. These methods are prohibited by the manufacturer's. So, one question. Why would you want any additional liability? And I'll leave it there.

When it comes to wool, the only approved "mechanical agitaiton & mechanical extraction" is the CRB machine. Get use to "mechanical entrainment" aka "mechanical extraction". The CRB machine performs dual function (simultaneously) as a mechanical entrainment system. Agitaiton, this is chemical distribution and soil disruption. Second, mechanical extraction of "heavy, coarse" dry soils that are "entangled, trapped and embedded" within the "effective pile". Oh, vacuuming covers all dry soils on the wear surface, however it's primarily for "fine, lightweight" dry soils which accounts for approx. 40-50%. Understand, I'm giving you what most have never seen yet. Shit on it and it's on you not me, LOL! But if you don't learn from this, someone will, even me! I'm not coming at you, I'm coming after the foundation that got you to this point.

The brush denier is designated by the color white/ clear typically, softest .17mm bristle thickness. Yes, wool will shed "some" or a "lot" if you compare it a BCF.

I'm bored and hope I've shared enough for not only you to get right, but others as well. I'm raising the bar! WE can do better. I want the best for anyone in this business. I feel pain like no other and the reckoning is here! I can make you the best cleaner or the worst. It's up to you with what I've provided you. Again, I'm not attacking you or trying to be little you. This me, however my promise is to continue to work on my communication skills. So, please be patient.

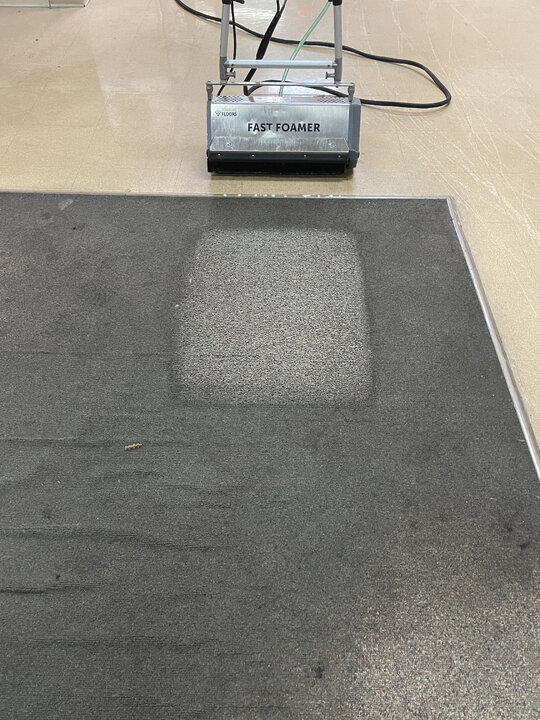

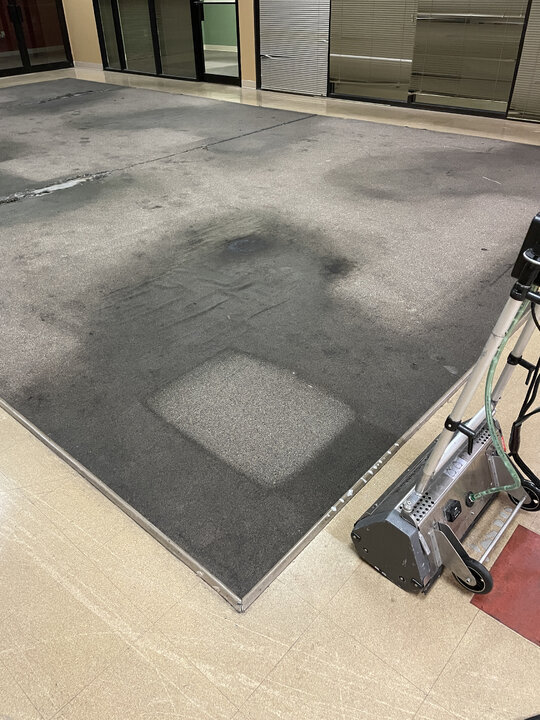

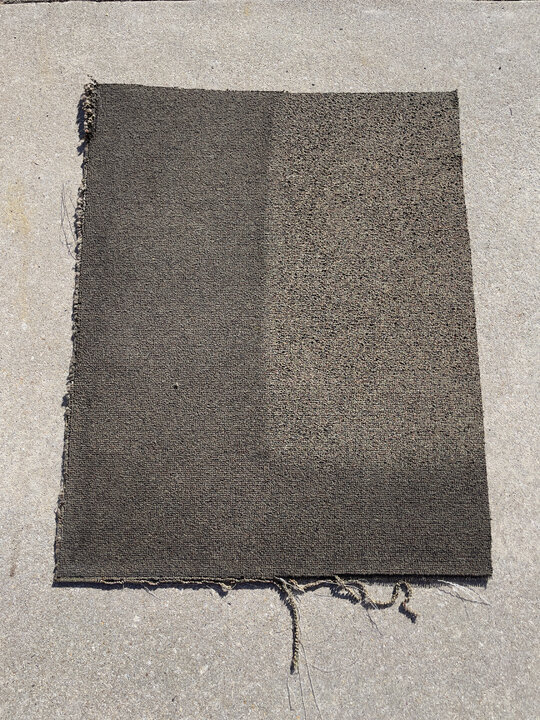

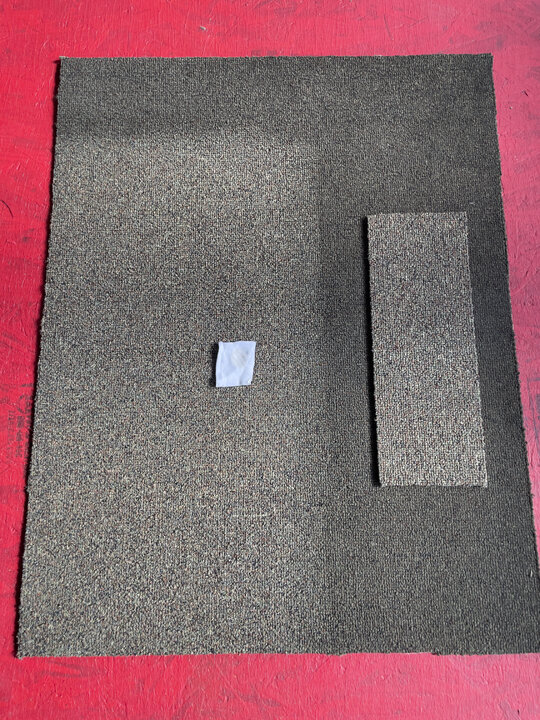

See the attached photos and tell me and everyone how the "Fast foamer would not work in this application".

Mikey P said a lot of you guys are friends and go back and forth and this is just a tight community, so don't be offended. LOL! Sounds like my kind of sandbox!

If you want to measure dicks, LOL. One example: We can clean a 5 story bldg over 70K sqft plus upholstery yada yada three Fast Foamers over a weekend (Sat & Sun) with time to spare. This system truly cleans. Rotary is dead kid and I'll keep kicking it. They knew rotary was bad in the 80's. Let that sink in. Why do they want you using it? Start asking questions. Wakey, Wakey sleepy head. Rotary is NOT an ENTRAINMENT SYSTEM! "They" have either intentionally suppressed the CRB technology "mechanical entrainment" or just didn't recognize it, either way. There is no going back to sleep! My work is copyrighted and will be out soon! Didn't you know... There is a MANDATE!

I GOT SO MUCH CONTENT! THIS INDUSTRY IS GOING TO SEE A MAJOR SHIFT! RELAX AND BREATH IT IN. WE GOT THIS! Disclaimer: WRE and TM's aren't going anywhere. I've broken it all down, but rotary is the past!

Rotary regardless of Oscillation is not even comparable when it comes to cleaning. The CRB machine removes 30-40% of dry insoluble soils which are "entangled, trapped and embedded" within the effective pile which vacuuming and WRE CANNOT REMOVE! Absorption is the least effective method and not as efficient as a CRB and why it is no longer used. It is counter productive. It doesn't lift the pile, detangle, dislodge, or remove embedded dry soils. It pushes soils down and residues accumulate. Understand the "ENTRAINMENT" methods and the intervention hierarchy AIR > MECHANICAL (CRB AGITATION AND EXTRACTION/ QUASI-FLUID) > WATER. The CRB bridges all fluids creating an "ENTRAINMENT TRIFECTA" aka "ENTRAINMENT TRIAD". We lead with physics not chemistry!I dont think the commercial client cares one bit about how drier or faster your cleaning method dries. It will be dry by the time the office opens in the morning. Whittaker CRB Orbot Cimax, hell 175 swing machine all with a good encap, vacuum before and after….same sheet. Brilliant results in the hands of a good operator.

So, yeah all those methods or systems may work, but it's "wrong" in the sense of lumping any rotary type system in with a CRB machine. Saying, "I don't think the commercial client cares one bit...". If the customer views their carpet as an investment, I think they care and if they look at it as a "consumable", well you do you. I try to do the best for others. What if a "mechanic" (trusted professional) that services your car was buying filters on TEMU or whatever, LOL, because the "mechanic" doesn't think most people care about what is used on their cars. Ultimately creating a "delayed consequence dilemma" because in 3-5 years your engine starts knocking. You find out. How do you feel now? Karma, perhaps. However, it's because we assumed something, why did we render this choice? Selfishness, tired of killing yourself, etc. The reason doesn't matter. You do better we all do better.

If you say... "X" is faster. I'll fly to your location and make you prove it! This is your mind ******* you! If I can save you just one (1) second per hour (8 hour day) over 20 years of working and if you're a "real" cleaner, LOL. This is peanuts. I'll give you about 12 hours of your life back. That's just one second, what do you think we can do saving a minute per hour, an hour per day or gain an extra hour of revenue? If anyone knows this ******* industry and how brutal it can be it's me. This is not lost on me and why I'm here. DO NOT BE MISTAKEN. I can still do a SUPER HERO LANDING like no other, they just hurt more.

When it comes to the encapsulation extraction method. It does NOT include rotary! The method was corrupted by the IICRC! The method was introduced with a CRB machine, specifically CCI/ CCA legendary TM series, most famously trademarked the "Great Little Scrubber" later "GLS" and we got Whittaker's GLS system with Crystal Dry, by big Dick Whittaker! C'Mon! It's funny. If you know you know. No disrespect! Whittaker is a LEGEND! I think he has more golf patents than cleaning patents, LOL. I've got to hear the back story because some amazing stuff was going on in the industry from the late 70's through the 90's with nylon fiber and specifically polymers and DuPont at the lead! Well, trying to keep it or regain it. DuPont sold it's "Capture" dry compound to Milliken circa1983 shortly after inventing it and Millicare emerged circa 1984 I believe. Whittaker was a Millcare CRB and dry compound supplier before Crystal Dry emerged. What did Whittaker know or who did he know? You curious? I know I am.

We're pulling back the curtain!

Wait till it all comes out. Of course, You'll need to be a real veteran to fully appreciate it, but at some point, you'll look back and say... "That was that ******* guy that called me out on Mikey'sBoard.

We'll get into encapsulation formulas at some point soon! We can discuss what is considered a "good encap". There's a lot of misinformation on this subject as well.

Hey, thanks for listening to my shit! Seriously!

Anyone reading this. Appreciate where you're at, specifically at this time. Mark the date! When I entered this industry, I walked among legends and DuPont "Demigods" if you will and had no ******* clue I was being passed sacred science, physics, chemistry, mechanical engineering, etc. This is why I was different and never knew it. Even with mentors like Bill Luallen in his classic soft spoken voice saying..."Buddy... you're different than other cleaners. You are a "DeWeese disciple" (my cleaning mentor was the lead when DFS entered the commercial floorcare market). I never really understood this until maybe a year ago or so. Don't listen to me because of trigger words like "DuPont". The point is, we lead with science. The science does not lie, people do!

Last edited:

If I answer late (timing wise) or somehow incorrectly, bear with me. I don't do much posting or social media. I move at the speed of light. As anyone can see, I have a lot on my mind. Again, I don't know how much time I'll be on here to post. As this is a distraction for me, however as I mentioned in one of the posts. I love the forum and conversations. Thanks Mikey P! You guys are great, my brothers. I just have limited time with the work that needs to be done in this industry. I'll assist where I can and respond or post when I can. Thanks!

icleancarpetz

Member

- Joined

- Mar 7, 2015

- Messages

- 1,703

- Name

- Rafael Samson

Vacuum, 2x Oxy Encap, scrub, pad, done.

Pass Go and Collect $200

kiss

Pass Go and Collect $200

kiss

Jim Pemberton

MB Exclusive.

- Joined

- Oct 7, 2006

- Messages

- 12,819

- Name

- Jim Pemberton

Having been a part of our industry for over 50 years now, including during my time working with S100 and all of the above named people, I find these comments and observations to be both interesting and entertaining.

I hope one of these gentlemen will be in Indianapolis.

I hope one of these gentlemen will be in Indianapolis.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

I hope one of these gentlemen will be in Indianapolis.

I have not heard from them, they are missing a HUGE opportunity when you consider all who will be in attendance

www.mikeysfest.com

Where does the dirt go?"water rinse extraction - A method of cleaning in which, following dry soil removal, a liquid cleaning solution is applied and then manually or mechanically agitated throughout the carpet pile. After an appropriate dwell time, suspended soils are rinsed under pressure with a hot or cold water-based solution (with frequently-used areas being rinsed at least twice), and extracted via wet vacuums. Carpet pile is then groomed and dried as necessary".

I know this is a power play and I like to have fun too! However, this is not why I'm here. Why say, Hot Water Extraction (HWE) instead of "Steam Cleaning"? Why do some use "Steam" while others use "Hot Water"?

Again, I'm not trying to goat you. We know "Steam" was challenged and why we got HWE and when it comes to WRE, we have plenty of thermal energy with 60-75 degree water as it relates to the Kelvin scale. Thermal, temp, heat is relavent to "compacted soiling" aka heavy organics, aka dry-solvent solubles yada yada. I know more about methods and how they work than most.

It's like "Steam". I'm sure one of your stewards has the definition given to Bane from a DuPont chemist. That's when we start talking about cleaning. Otherwise, we're just sharing opinions. Science overall! I like you Mikey P! We're going to be good friends.

Please don't! This is not going to end well for you. Let's break this down. You have no experience with the Fast Foamer and no idea how it works and if it would be applicable as you are obviously not qualified to be speaking on this. I'm not here to destroy, but understand how I work. I will come at you with peace and willing to share all my knowledge to you or anyone who wishes to better themselves and the industry. Before I start. When I say "wrong", it's not 100% wrong because you have not been taught properly. I was taught properly and it still took me years to master it. So, I'm not attacking you. Even I can be "wrong". There is "wrong" as in appropriate, proper and adequate. "Wrong" as ineffective or inefficient.

1. Vacuuming. There is no reason to use a vacuum that aggressively on a wool carpet. Regardless of your perceived soil load. The vacuum isn't supposed to work on mechanical agitation. Yes, there is some, however it works by using two unique air flows. One created by the brush roll spinning at about 4k RPM. This RPM creates a vibration that separates the micro particulate 10 microns or less, typically about 2.5 microns which are primarily responsible for make carpet look "dirty". Couple that with a soluble aka binding agent aka the "sticky stuff". The brush roll creates a low pressure zone that pulls these micro particulate separating it from the fiber, suspending and "entraining" it into another low pressure air flow created by the vac motor. It's called "entrainment". Get use to that word because I've expanded on the science of cleaning particularly leading with physics fluids and the introduction of "mechanical entrainment" which creates an "Entrainment Trifecta" AIR (vacuuming) > MECHANICAL (CRB MACHINE, the brushes act as a QUASI-FLUID) > WATER (water rinse extraction). Vacuuming isn't "dry soil removal", it is "loose dry soil removal", Oh! I guess the cat is out of the bag, I've revised the principles, well not revised, expanded really and created the "principles of soil removal" for commercial textile floor coverings.

2. Regarding Cimex. This is where you done ****** up! I'm not even going to speak on this as it is insanity. These methods are prohibited by the manufacturer's. So, one question. Why would you want any additional liability? And I'll leave it there.

When it comes to wool, the only approved "mechanical agitaiton & mechanical extraction" is the CRB machine. Get use to "mechanical entrainment" aka "mechanical extraction". The CRB machine performs dual function (simultaneously) as a mechanical entrainment system. Agitaiton, this is chemical distribution and soil disruption. Second, mechanical extraction of "heavy, coarse" dry soils that are "entangled, trapped and embedded" within the "effective pile". Oh, vacuuming covers all dry soils on the wear surface, however it's primarily for "fine, lightweight" dry soils which accounts for approx. 40-50%. Understand, I'm giving you what most have never seen yet. Shit on it and it's on you not me, LOL! But if you don't learn from this, someone will, even me! I'm not coming at you, I'm coming after the foundation that got you to this point.

The brush denier is designated by the color white/ clear typically, softest .17mm bristle thickness. Yes, wool will shed "some" or a "lot" if you compare it a BCF.

I'm bored and hope I've shared enough for not only you to get right, but others as well. I'm raising the bar! WE can do better. I want the best for anyone in this business. I feel pain like no other and the reckoning is here! I can make you the best cleaner or the worst. It's up to you with what I've provided you. Again, I'm not attacking you or trying to be little you. This me, however my promise is to continue to work on my communication skills. So, please be patient.

See the attached photos and tell me and everyone how the "Fast foamer would not work in this application".

Mikey P said a lot of you guys are friends and go back and forth and this is just a tight community, so don't be offended. LOL! Sounds like my kind of sandbox!

If you want to measure dicks, LOL. One example: We can clean a 5 story bldg over 70K sqft plus upholstery yada yada three Fast Foamers over a weekend (Sat & Sun) with time to spare. This system truly cleans. Rotary is dead kid and I'll keep kicking it. They knew rotary was bad in the 80's. Let that sink in. Why do they want you using it? Start asking questions. Wakey, Wakey sleepy head. Rotary is NOT an ENTRAINMENT SYSTEM! "They" have either intentionally suppressed the CRB technology "mechanical entrainment" or just didn't recognize it, either way. There is no going back to sleep! My work is copyrighted and will be out soon! Didn't you know... There is a MANDATE!

I GOT SO MUCH CONTENT! THIS INDUSTRY IS GOING TO SEE A MAJOR SHIFT! RELAX AND BREATH IT IN. WE GOT THIS! Disclaimer: WRE and TM's aren't going anywhere. I've broken it all down, but rotary is the past!

View attachment 130404 View attachment 130405 View attachment 130407 View attachment 130408 View attachment 130409 View attachment 130410 View attachment 130411 View attachment 130412 View attachment 130413

Latest posts

-

-

-

-

-

-

Suggestions for removing strong VOC smell from concrete slab?

- Latest: MasterCarpet

-

-

-

-

-

-

-