dgardner

Moderator

I posted this on another board, mainly to help the less experienced folks out there. Not sure if any of you seasoned vets can use it, but just in case, I'll post it here too.

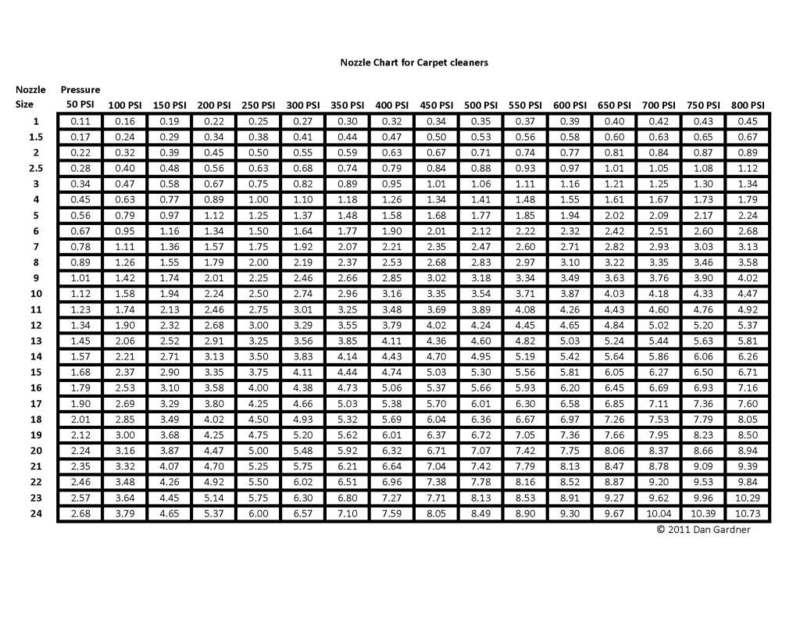

First up is a standard nozzle flow chart. It seems every time I need a value, the charts out there don't list it. Maybe pressure on the chart jumps from 250 psi to 500, and I need 400, or it lists flow for a 25 jet and I'm looking for a 24. Anyway, I punched the flow calcs into a spreadsheet and did pressures every 50 psi from 50 to 800, and jets from 1 to 24. Like every other nozzle table, pressure is at the jet.

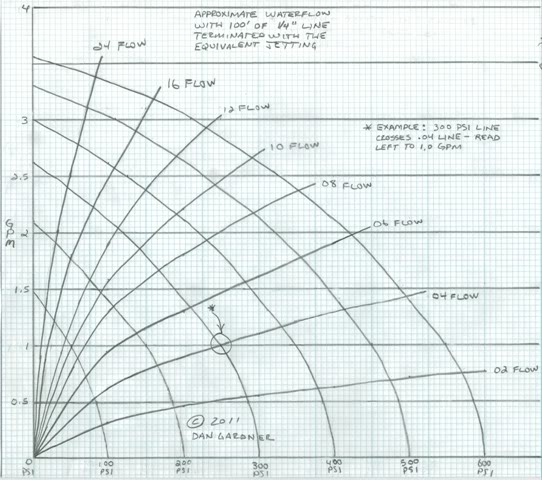

Last is a hand-drawn chart I did a while back to approximate flow from a jet (or jets) at the end of a 100 foot 1/4" hose. It overcomes the major limitation of the standard nozzle flow charts that don't take hose friction losses into account. It doesn't figure losses through the valve or wand plumbing, so your actual flow will be a little lower, but it is worlds closer to real life. The pressure here would be ATM with wand keyed and water flowing.

First up is a standard nozzle flow chart. It seems every time I need a value, the charts out there don't list it. Maybe pressure on the chart jumps from 250 psi to 500, and I need 400, or it lists flow for a 25 jet and I'm looking for a 24. Anyway, I punched the flow calcs into a spreadsheet and did pressures every 50 psi from 50 to 800, and jets from 1 to 24. Like every other nozzle table, pressure is at the jet.

Last is a hand-drawn chart I did a while back to approximate flow from a jet (or jets) at the end of a 100 foot 1/4" hose. It overcomes the major limitation of the standard nozzle flow charts that don't take hose friction losses into account. It doesn't figure losses through the valve or wand plumbing, so your actual flow will be a little lower, but it is worlds closer to real life. The pressure here would be ATM with wand keyed and water flowing.