Well I see that incorporating Cerakote has created a bit of chatter here, let me attempt to address some of the questions surrounding the product application.

First of all

Legend Brands (

Sapphire Scientific and

Prochem) is constantly investigating engineering innovations that not only improve product cleaning performance but extend product life as well as improve user experience.

The popularity (AKA sales) of the

570 platform speak for themselves and while

Legend Brands could sit back and enjoy the fact that Prochem and

Sapphire truckmounts are the #1 choice of cleaning and restoration contractors we have chosen to invest in continuous improvement.

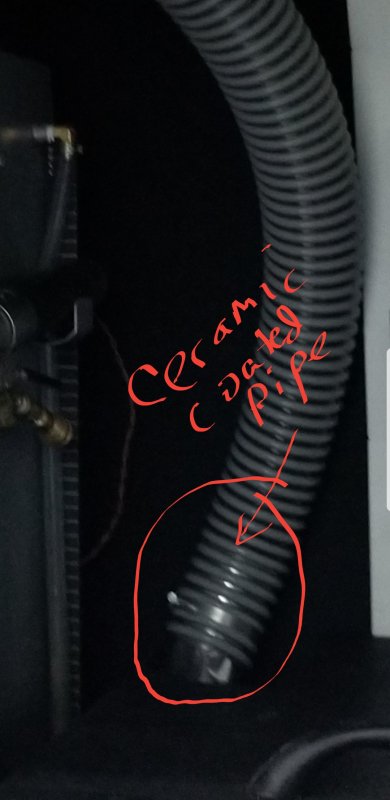

Regardless what truckmount you use heat is our friend and also our enemy. Newer engines run leaner and incorporate catalytic exhaust systems. We recognize that thermal radiant heat from exhaust not only can lead to degradation of truckmount components but also makes van interiors dang hot. With that in mind we searched for solutions to move the heat out of the truck and through the exhaust.

Our search lead us to the automotive and motorcycle aftermarket high performance industry. Cerakote, as the name implies is a ceramic coating that involves Cerakote material applied through a specialized process. Creakote is widely used in high performance engine applications to reduce thermal radiant heat from high temperature exhaust components and move the heat down the pipe and away from the vehicle. It is a proven product in both high performance vehicles and as noted the firearm industry. We view Cerakote as a additional engineering step in the evolution of truckmounts.

In regards to testing the use of thermal imaging and standard infrared thermometers is ineffective as the Cerakote is a reflective coating thus readings simply bounce back. In order to accurately test we directly placed thermal probes to the surface as well as in the air stream of a Creakote treated and a non treated stainless steel exhaust component. 1000 degree heated air was directed/blown thru the exhaust component for two hours and data was recorded on a data tracker. The results were a 30% reduction in radiant heat on the Cerakote treated exhaust part.

Since watching a 4 hour video of a data tracker would be a cure for insomnia we chose to do a more visual test for video demonstration. By simply heating a stainless steel tube, 1/2 treated with Cerakote the other half untreated the results speak for themselves. Simply put Cerakote does what it is intended to do, moves the heat out of the van.

Additionally the new Apex 570 incorporates new radiator that was specifically engineered by C&R Racing for

Legend Brands. C&R manufactures radiators and cooling solutions used by top tier race teams. The new radiator incorporates extruded tube and race-fin configuration to provide engine cooling you can rely on in the most extreme heat conditions.