GeneMiller

Member

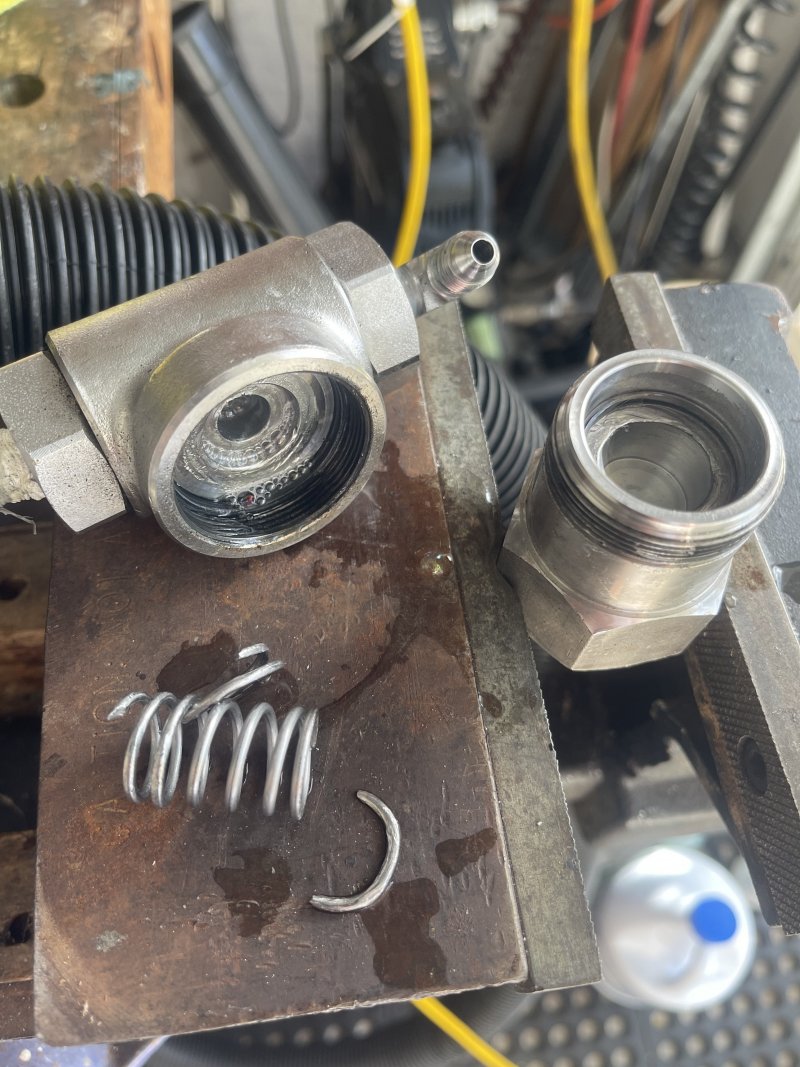

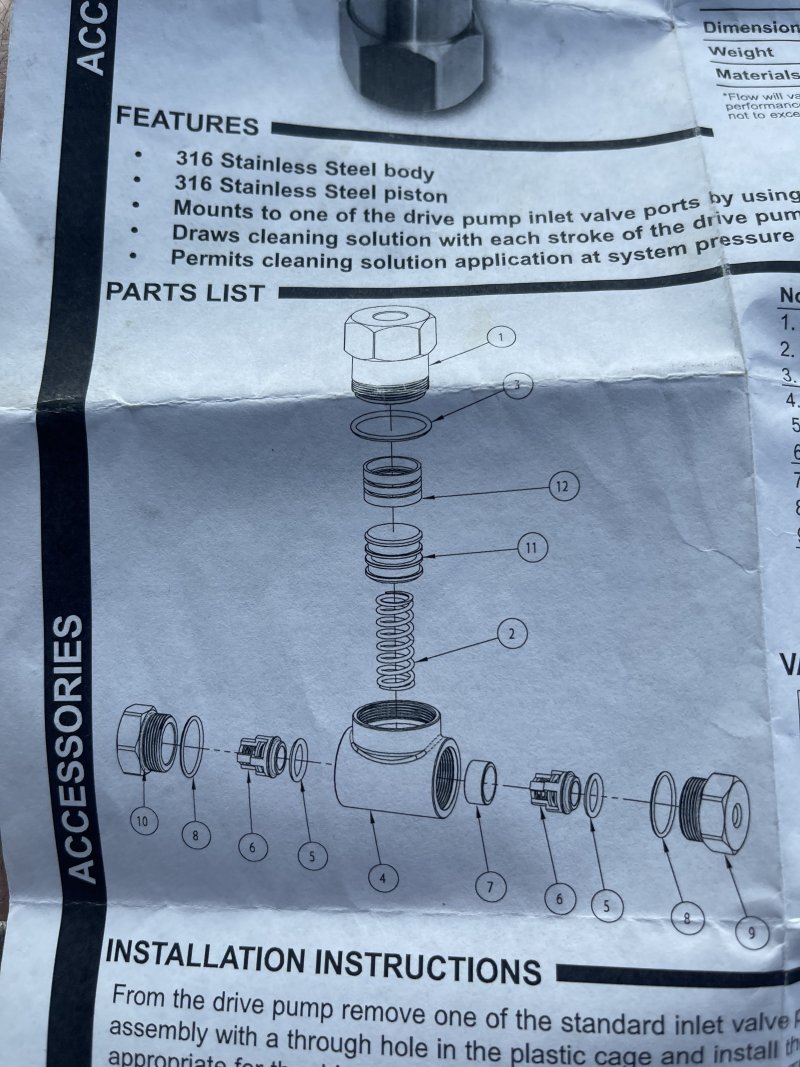

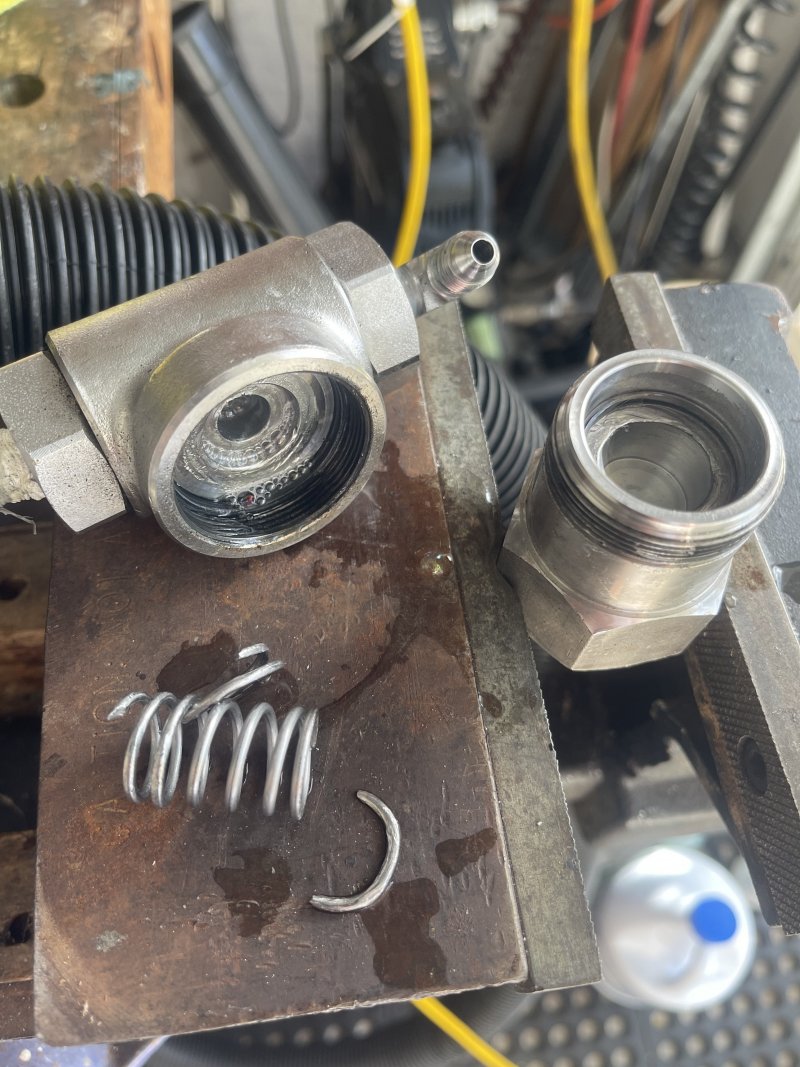

This is the second time the chemical pump died. The last time GP replaced it under warranty. The springs keep breaking. I wish I knew how many hours from the last time it broke. This one was installed in April of 2019 but I didn’t right down the hours.

Am I the only one having the problem with the springs breaking I run ice as my main rinse. When we clean tile I run ammonia.

I run ice as my main rinse. When we clean tile I run ammonia.

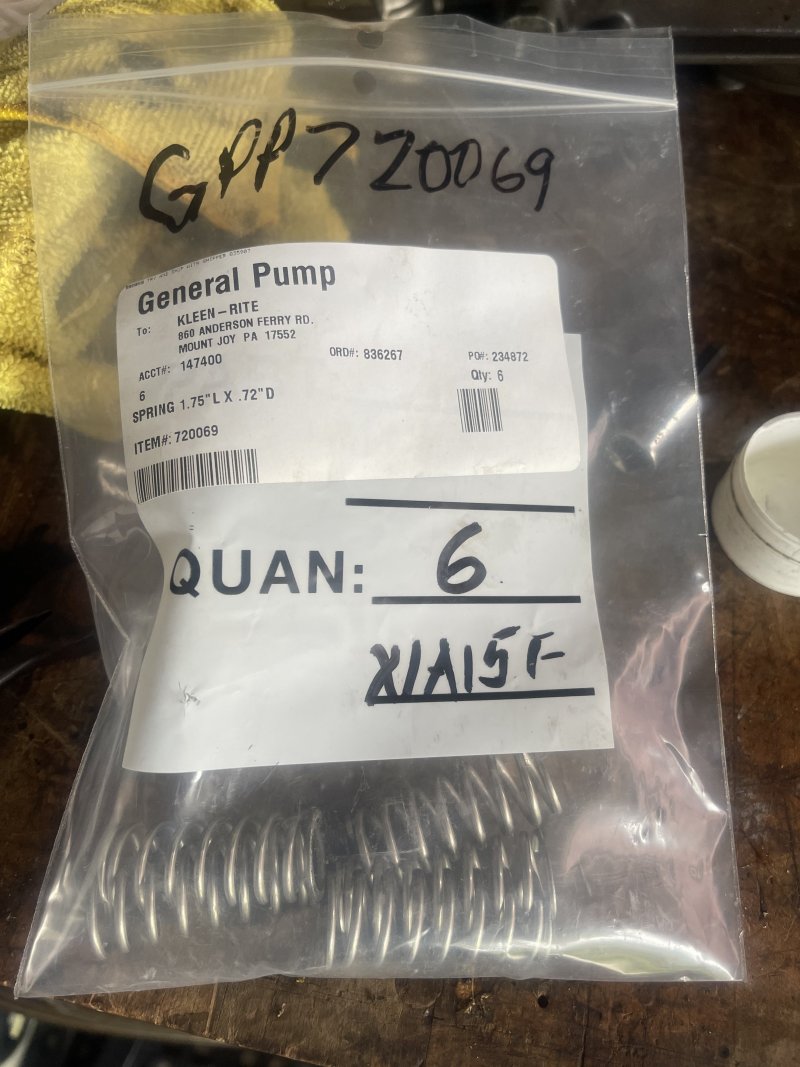

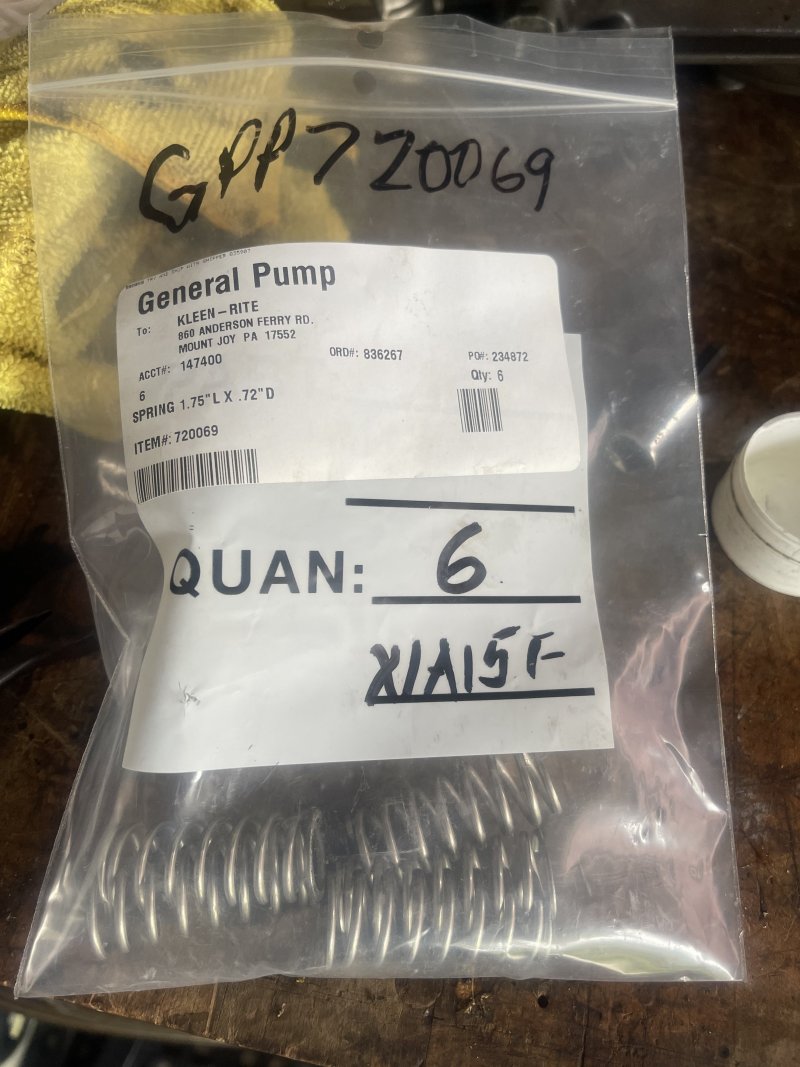

Luckily I bought 6 springs the last time as back ups.

Am I the only one having the problem with the springs breaking

Luckily I bought 6 springs the last time as back ups.