Mikey P

Administrator

EXTRACTION METHOD

Dry vacuum all areas, with extra passes made in high traffic areas. A north/south/east/west pass pattern is recommended to achieve the best result. Keep in mind, most vacuum cleaners remove the most particulate soil when the machine is being pulled toward you, so slow down during this stage.

Application of pre-spray formulated for heavy soil and synthetic fibers.

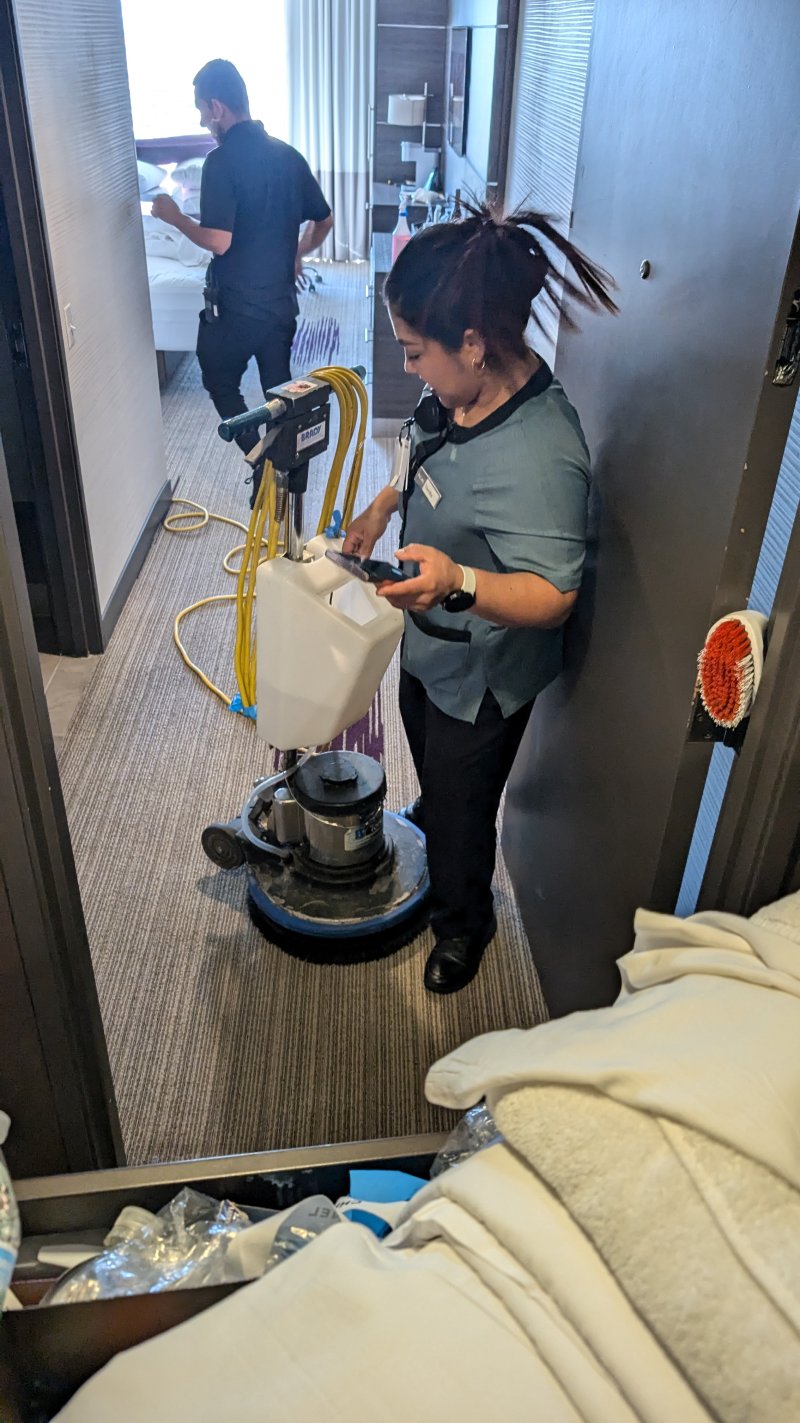

Use a 175 or OP machine equipped with a Fiber Scrubbing Pad to agitate. CRB machines can work in lighter soil conditions but are too lightweight to break greasy soil loose in most situations, regardless of how stiff the brushes are.

Allow for dwell time

Extract with a wand designed for specifically cleaning pile or glue down carpet. Extraction wands should be modified to the task at hand in regard to jetting, flow rates as well as glide type. (see section *** for more info)

Use of a rinsing agent that has cleaning ability as well as being able to neutralize high pH pre-spray is recommended

Perform extra extraction strokes with your wand strokes if results are unsatisfactory, followed by addition dry extraction passes.

Repeat steps 2 through 6 if needed. A Rotary Extractor may be needed in extreme cases. Be sure to feel the carpet after using an “RE” to determine if any additional dry strokes from your extraction wand will be beneficial, which is often the case, especially on floor with unlevel concrete subfloors.

A floor machine and a cotton blend type pad to go over the area again to remove additional soiling and moisture may be beneficial as well. This last step process is known as “Post Padding”.

Use air movers to facilitate quicker drying if needed as wicking is very common in these situations.

*With any method or procedure, it is up to the operator or technician to determine if any warranties are in place that may have set limitations on how aggressive one can get with both chemistry and agitation equipment.

Dry vacuum all areas, with extra passes made in high traffic areas. A north/south/east/west pass pattern is recommended to achieve the best result. Keep in mind, most vacuum cleaners remove the most particulate soil when the machine is being pulled toward you, so slow down during this stage.

Application of pre-spray formulated for heavy soil and synthetic fibers.

Use a 175 or OP machine equipped with a Fiber Scrubbing Pad to agitate. CRB machines can work in lighter soil conditions but are too lightweight to break greasy soil loose in most situations, regardless of how stiff the brushes are.

Allow for dwell time

Extract with a wand designed for specifically cleaning pile or glue down carpet. Extraction wands should be modified to the task at hand in regard to jetting, flow rates as well as glide type. (see section *** for more info)

Use of a rinsing agent that has cleaning ability as well as being able to neutralize high pH pre-spray is recommended

Perform extra extraction strokes with your wand strokes if results are unsatisfactory, followed by addition dry extraction passes.

Repeat steps 2 through 6 if needed. A Rotary Extractor may be needed in extreme cases. Be sure to feel the carpet after using an “RE” to determine if any additional dry strokes from your extraction wand will be beneficial, which is often the case, especially on floor with unlevel concrete subfloors.

A floor machine and a cotton blend type pad to go over the area again to remove additional soiling and moisture may be beneficial as well. This last step process is known as “Post Padding”.

Use air movers to facilitate quicker drying if needed as wicking is very common in these situations.

*With any method or procedure, it is up to the operator or technician to determine if any warranties are in place that may have set limitations on how aggressive one can get with both chemistry and agitation equipment.