You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New upholstery tool devlopment is coming along..

- Thread starter Mikey P

- Start date

In its present form it doesn't look very good for contouring. Flat surfaces maybe.I have additional ideas for the Glide, once I've determined the final design, it'll be sent to the tool fabricator for them to make the titanium head around it.

That could be a first....

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

What tool do you consider good for contuouring?In its present form it doesn't look very good for contouring. Flat surfaces maybe.

A single narrow slot tool I can partially block off while cleaning tight corners, piping, etc.What tool do you consider good for contuouring?

Also a open spray for misting panels if necessary but I always did 95% of my upholstery with a portable.

It also depends on whether you are designing a TM tool or a portable tool.

Some features are good for one but not the other and you will never satisfy everyone with one tool.

I'm still partial to a stainless open jet tool Jim Pemberton sold me probably near 40 years ago but have 5-6 different tools depending on the need.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

A single narrow slot tool I can partially block off while cleaning tight corners, piping, etc.

Also a open spray for misting panels if necessary but I always did 95% of my upholstery with a portable.

This tool has both of those features, AND the ability to take off the gliide in seconds if needed, which other than cleaning eges of steps and wanting to avoide tackless damage, I can't think of why anyone would want to.

royalkid

Supportive Member

- Joined

- Apr 14, 2009

- Messages

- 885

- Name

- Gulf Coast Carpet Care

I've had the old school tools, tried 2 different dri-masters (liked em' but snagged and got clogged easily). The Mytee tool is awesome...best I've used.

Getting sic'er by the minute...

View: https://youtu.be/_v0bQlEUPBs?si=a5dpKjr4Kk_85ndp

Inch and a quarter ultra flexible vac hose with swivel cuff, in 10, 15 & 20' choices.

The optional brass bypass assembly will come with a protective bag for those concerned about scratching delicate floors.

And did I mention the head will most likely be made out of titanium for a 35% weight reduction?

View attachment 130402 View attachment 130403

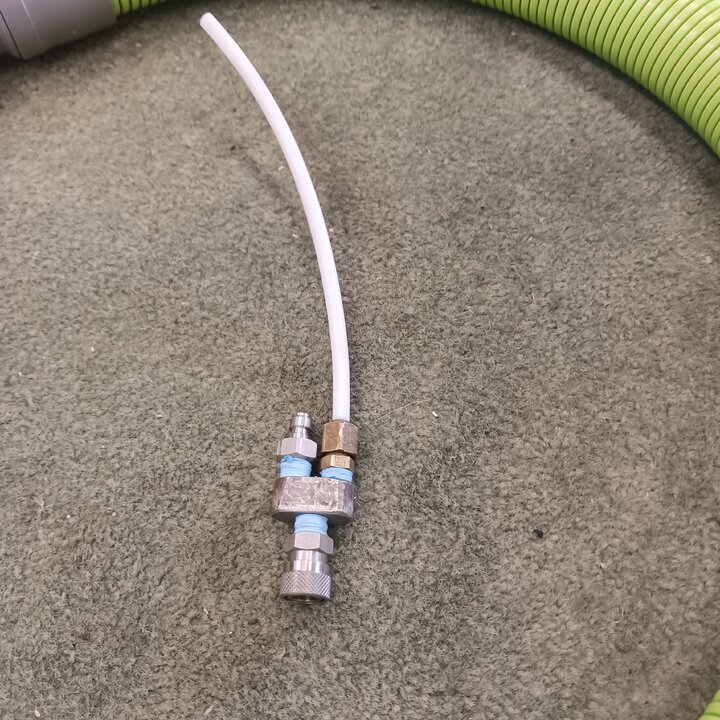

That bypass appears to be where the hose connects and youll have significant heat loss when you stop squirting solution for any length of time. Where as if you put a continuous bypass closer to the head your solution will stay hotter on a standard older prochem tool and a newer sapphire scientific tool i use a piece that i fabed up from kleanrite solvent attachment parts a small 2×1/8by 1-1/8 stainless manifold block 1- 1/8 mpt×1/8 fqc 1-1/8 mpt× 1/8 mqc and a kleanrite 1/8 mpt ×1/4 compression fitting internally threded for small bypass orifice to bypass at the attachment instead of the end of the hose works best added benefit is it is easily removed if necessary the bypass cost about 30.00 to build with off the shelf parts and can be made to work with any tool with internal solution hose so if you set the tool down to prespray or get useing vacuum for any length of time you dont have to heat up 10 or so feet of internal solution hose just squeeze the trigger and have nearly instant full heat! Better yet if you could find and use a valve that squirts when you squeeze it and bypasses when you let off the trigger. I assumed that was how the prochem tool worked with its little valve on the side but sadly not true . It bypasses but only when you squeeze the trigger

Last edited:

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

That bypass appears to be where the hose connects and youll have significant heat loss when you stop squirting solution for any length of time. Where as if you put a continuous bypass closer to the head your solution will stay hotter on a standard older prochem tool and a newer sapphire scientific tool i use a piece that i fabed up from kleanrite solvent attachment parts a small 2×1/8by 1-1/8 stainless manifold block 1- 1/8 mpt×1/8 fqc 1-1/8 mpt× 1/8 mqc and a kleanrite 1/8 mpt ×1/4 compression fitting internally threded for small bypass orifice to bypass at the attachment instead of the end of the hose works best added benefit is it is easily removed if necessary the bypass cost about 30.00 to build with off the shelf parts and can be made to work with any tool with internal solution hose so if you set the tool down to prespray or get useing vacuum for any length of time you dont have to heat up 10 or so feet of internal solution hose just squeeze the trigger and have nearly instant full heat! Better yet if you could find and use a valve that squirts when you squeeze it and bypasses when you let off the trigger. I assumed that was how the prochem tool worked with its little valve on the side but sadly not true . It bypasses but only when you squeeze the trigger

View attachment 130444 View attachment 130445 View attachment 130446 View attachment 130447 View attachment 130448 View attachment 130449 View attachment 130450 View attachment 130451

Going to be a hard sell telling people they have to take their cuff and hose apart to get to the bypass which in your case doesn't even have an adjustment so you're going to be filling up your tank Non-Stop

I don't think he at that level is that important

I understand, for me , i pump so the amount of soulition going into the wastetank isn't an issue as far as removing the bypass ive only done that once. That was because i had to use my own water supply (waterpond) to do a large sectional. How about a valve like this one, this attachment was my inspiration to build bypasses for all my internal hosed attachments. It bypasses continously at the valve has a needle valve to adjust flow of the bypassed solution and can be turned completely off. As a mater of fact i thought that the prochem tool did the same by looking at it in the catalog and was really disappointed that it didn't. This is not my go to tool i use it mostly for rv and automotive interiors. But I do love how it keeps solution hot!Going to be a hard sell telling people they have to take their cuff and hose apart to get to the bypass which in your case doesn't even have an adjustment so you're going to be filling up your tank Non-Stop

I don't think he at that level is that important

I use pto's so i really don't have super heat i get around 200° at the truck when doing upholstery (frankinstien does have a hydramaster salsa unit installed) before when attachments had external supply hoses it wasn't that big a deal but now with 10+ feet of internal solution hose it doesn't take but a minute for the solution to cool and can take awhile to get the temp. up again . I don't care what anyone else says i prefer a consistent temperature and hot water cleans better than tempid or cold. Ive used the same attachments with near head bypass and end of hose bypass and no bypass. For me closer to the head is best. I actually use a modified (tee'd off for external m&f quick connects) dust downer at at the end of my stair tool when i have 200+ feet of hose on the ground to keep the solution hot there tooWhere do you find upholstery so grungy that you need 200+ to clean it?

hogjowl

Idiot™

- Joined

- Oct 7, 2006

- Messages

- 49,947

You have an uneducated, outdated and closed mind. You’ll do well here.

Idiot

Idiot

Thank you from what i understand thats quite a compliment coming from youYou have an uneducated, outdated and closed mind. You’ll do well here.

Idiot

Ya gotta start somewhere. Before there was an automobile there was a wheel for sureWe've gotten to the point where I think this may be the first time in cleaning tool history where, the Glide will dictate how the rest of the tool is made.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

If the mountains allow and the coast is clear I may be in your neighborhood May 1st through 4th, would you mind coming over and steam cleaning the mattress in the hotel?Ya gotta start somewhere. Before there was an automobile there was a wheel for sure

I don't know about cleaning the mattress but id like to meet up with yaIf the mountains allow and the coast is clear I may be in your neighborhood May 1st through 4th, would you mind coming over and steam cleaning the mattress in the hotel?

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,505

- Name

- sam miller

Well you can wet a piece of fabric out well with it.Once I finalize everything it'll take 8 to 10 weeks to have the new bodies made with my changes but the Glide should be ready in another couple weeks.

View attachment 129870

The Glide will fix the pushability...

When I first proposed the question of whether it should have a spray shield or not I was surprised at how many didn't think it needed it....

You tell me

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,505

- Name

- sam miller

Maybe a external vac hose that doesn't fight you as much.Sapphire uph tool is about the best tool on the market. What more does an uph need?

Bluetooth? Miniature heat exchange? Steam source for draperies? Autonomous guidance system? Spot and stain identifying system? UV lighting? Fabric identifying system? Firearm Magnet for hood jobs? Mace magnet for suburb jobs? Bottlem Cap opener? Tuna can opener for lunch break?

But that's about it

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

So you're saying guys who clean 4-5 sectionals a week compared to one or 2 or implant cushion cleaners

Yeah, and guys that like to use it for@ 4nch tool to detail out staircases , corners, mist and clean furniture or extreme soil work, all of which is tool will excel at

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,505

- Name

- sam miller

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

Isn't that the tool that has the jets aimed straight down?

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,505

- Name

- sam miller

Probably, I don't own one hahahaIsn't that the tool that has the jets aimed straight down?

Nate The Great

Member

- Joined

- Mar 29, 2008

- Messages

- 9,750

- Name

- Nate W.

I prefer the PCTI on upholstery production..

Latest posts

-

-

-

-

-

-

Suggestions for removing strong VOC smell from concrete slab?

- Latest: MasterCarpet

-

-

-

-

-

-

-