Yes this was left for dead, I'll stop back, I keep saying that it's just that I'm getting busy. more of a power trip.

He just got the testla. Wish I had a automatic

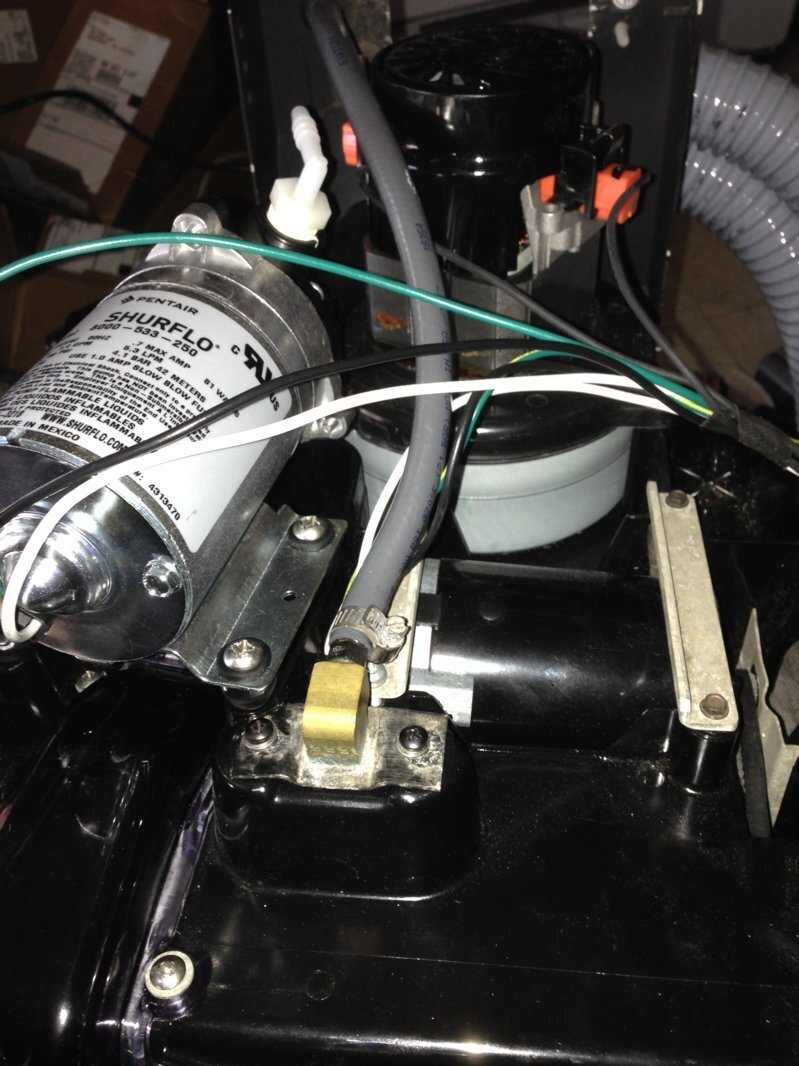

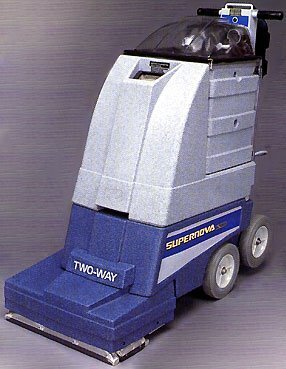

edic. I still just use the five star, have two and it's not to bad. I get great results. On my way! I have two other portables, a 700 and the super nova. I picked up a nice pressure line and 50 ft hose, I was thinking the super on a stair tool! Like to kinda cheap out with just a stainless shorty. No crazy Teflon or nothin. I use the spotter most on stairs. Like to just park the super it has 2 vacs, the work but I like to beef that up. I'm sure I put a new pump. Think it's only 250psi. This has two tanks and its I nice system.

he still thinks I'm not really hitting it with the proper pretreat. I showed him some photos of the before and after, he knows he waited to long last time ( 8 months)

he still thinks I'm not really hitting it with the proper pretreat. I showed him some photos of the before and after, he knows he waited to long last time ( 8 months)