Just held a private 3 Day RRT Class in NY and then spent an additional day to work with some of the students. Occasionally in a class we will have real 'Live' work to do and it is usually a very good experience.

Here is one room that had two 'Iron Burns' one moderate and one 'severe'. There was also damage along an edge that was repaired.

I enjoyed this event and thought I would share it to let some know what type of things are learned in a RRT Class.

severe iron burn, so deep even the pad was burned

Here was another burn but much less damage

Here one student is working on one burn mark

another student working on another burn mark

And another student working on one of ther burn marks with another

removing one of the burns

setting up the repair

cutting out the donor piece

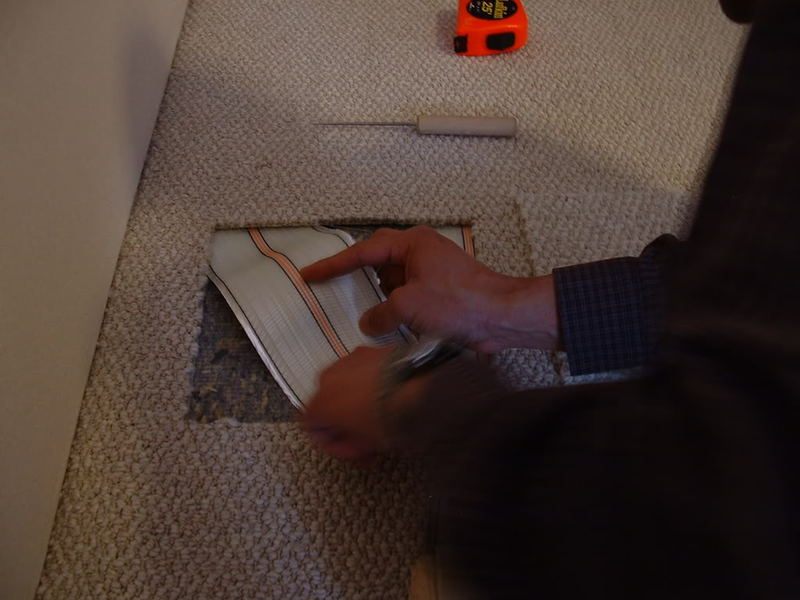

being sure it fits

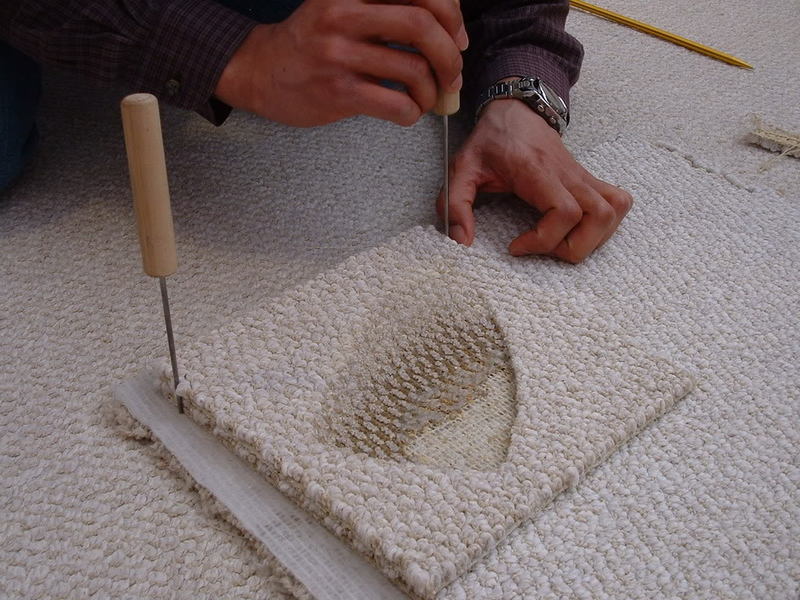

detailing the donor piece for a precision fit

using kool glide after sealing and securing all edges with a glue gun

Final details

Repairing edge damage

Finishing up putting everything together and a nice smile for the camera

Thought some might enjoy this and some might like to see some of what goes on in a repair class.

SA

Here is one room that had two 'Iron Burns' one moderate and one 'severe'. There was also damage along an edge that was repaired.

I enjoyed this event and thought I would share it to let some know what type of things are learned in a RRT Class.

severe iron burn, so deep even the pad was burned

Here was another burn but much less damage

Here one student is working on one burn mark

another student working on another burn mark

And another student working on one of ther burn marks with another

removing one of the burns

setting up the repair

cutting out the donor piece

being sure it fits

detailing the donor piece for a precision fit

using kool glide after sealing and securing all edges with a glue gun

Final details

Repairing edge damage

Finishing up putting everything together and a nice smile for the camera

Thought some might enjoy this and some might like to see some of what goes on in a repair class.

SA