Loren Egland

Member

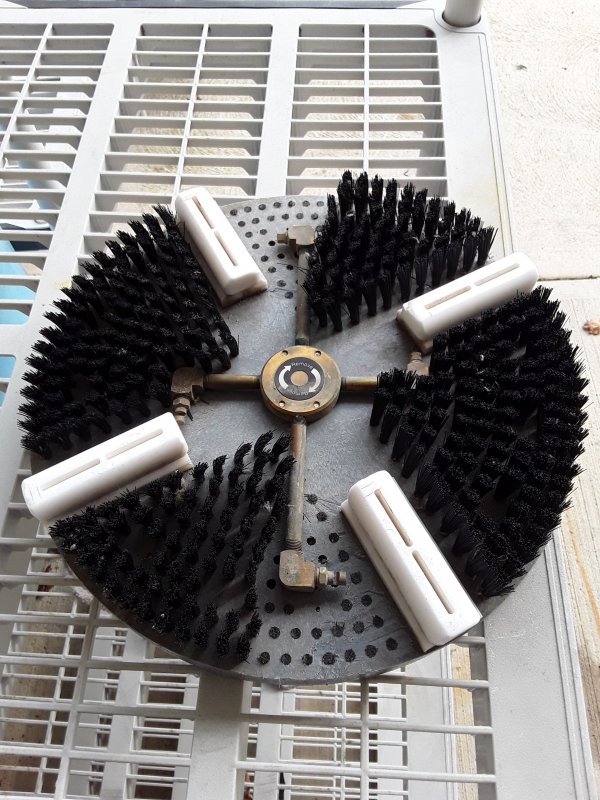

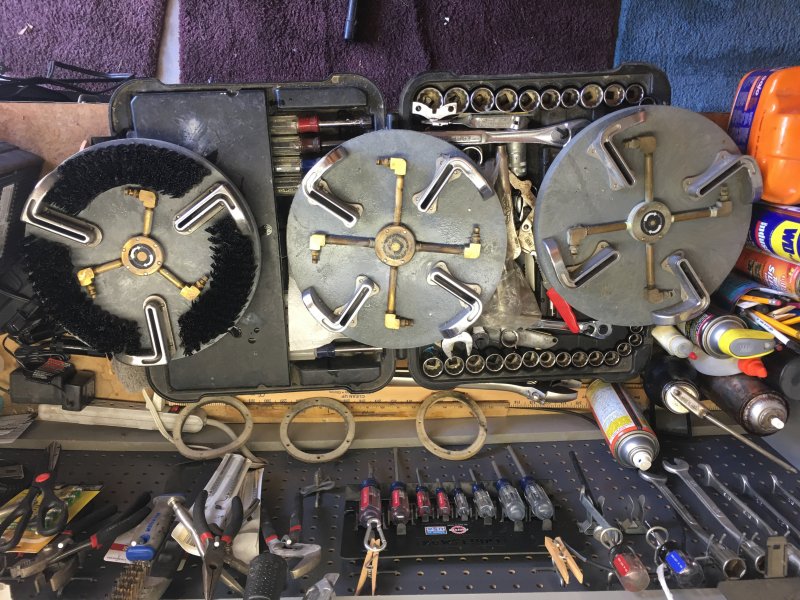

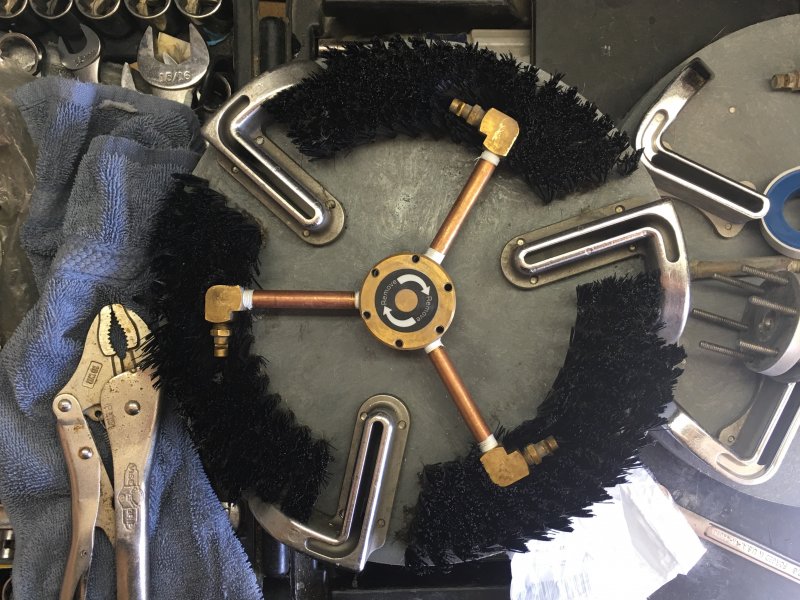

I picked up a used brush head at the annual Prolone swap meet in Sacramento. I thought I might like it on some of the polyester and olefin carpet. But am very disappointed in the design compared to my quad head.

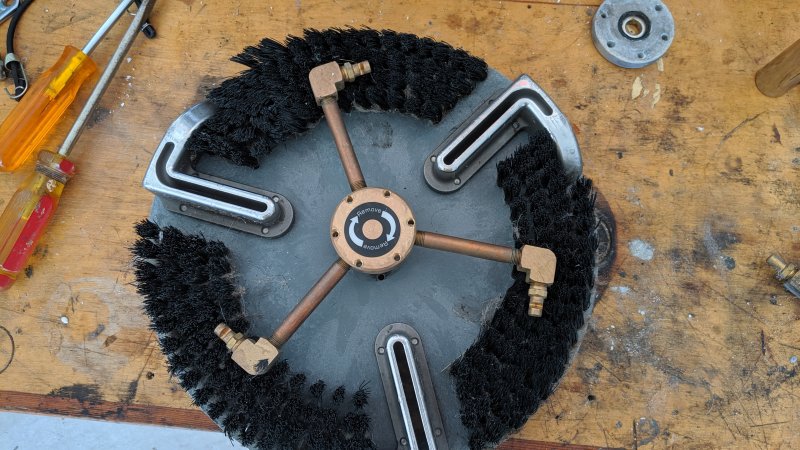

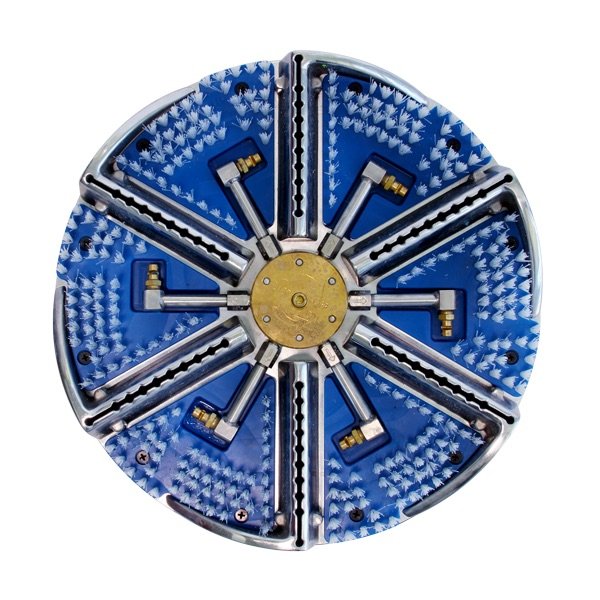

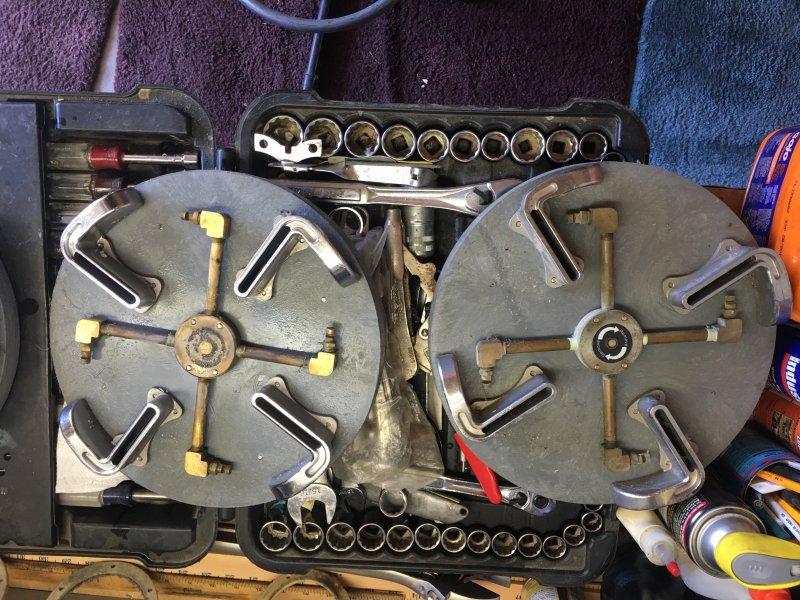

As you can see in the picture of these two cleaning heads side by side, the jet location on the quad is right in the center of the vacuum pick up port as it spins around during the cleaning operation and can thus pick up the water from the entire width of the spray.

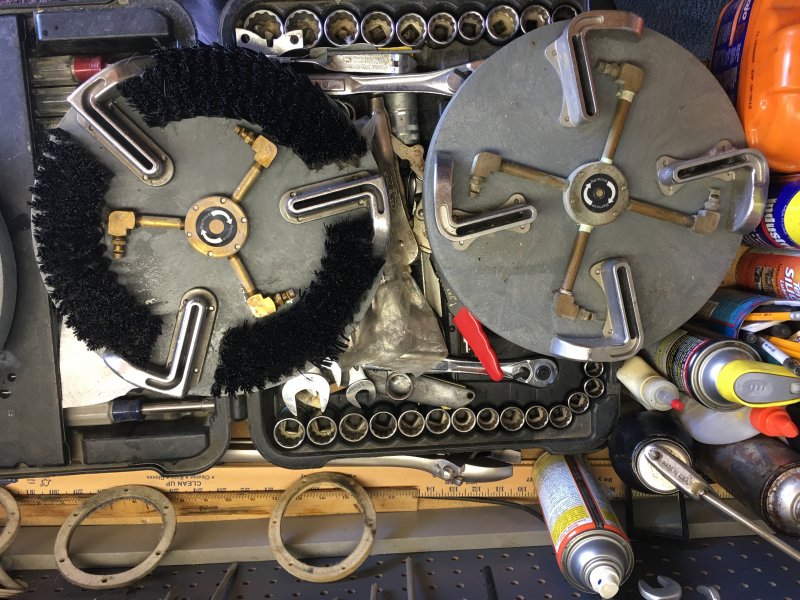

The brush head has its jets set further in toward the center hub and so as the head spins only about half the spray width is picked up by the vacuum port. The water from the other half of the spray width doesn’t get extracted immediately but just wets the carpet in that area because the water is not being extracted at all. If you want to hold the Rotovac in on spot, the area near the center axis just keeps soaking the carpet. That’s problem number one.

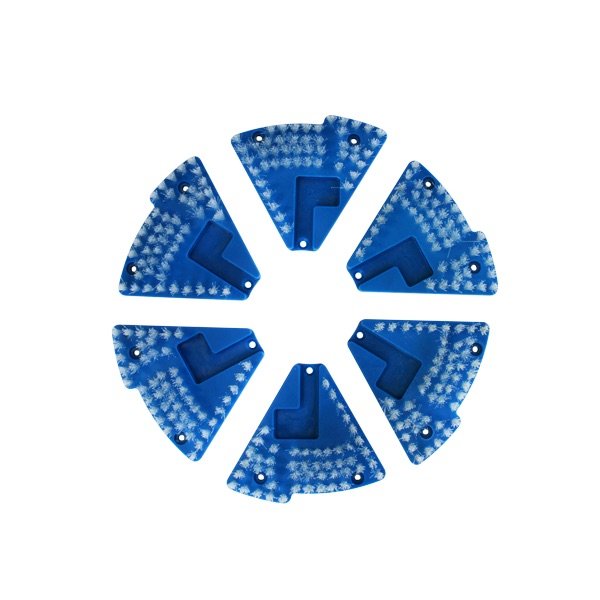

Problem number two is that the brush bristles themselves interfere with the spray width. You get no cleaning spray on the outside couple inches, so there is no getting close to anything due to the decreased width from brush interference. The cleaning path in side to side motion is probably closer to 8 inches than the 12 or so inches of the quad head. With the jet placement and brush spray interference, you may only be getting one inch or so of spray and extraction in the spin path.

Now I’m sure someone will tell me to just keep the machine moving and it will be fine. However, I would like to fix these design flaws. Have any of you tried to make a couple changes in the brush head?

My thinking is to change the jet location to the same position as my quad head. But the brush is in the way. Perhaps a scissors could cut a path in the bristles for the jets to lay in. I would think that would work but I haven’t tried it. Honestly I can’t imagine why the brush head was designed the way it is rather than the way I am suggesting.