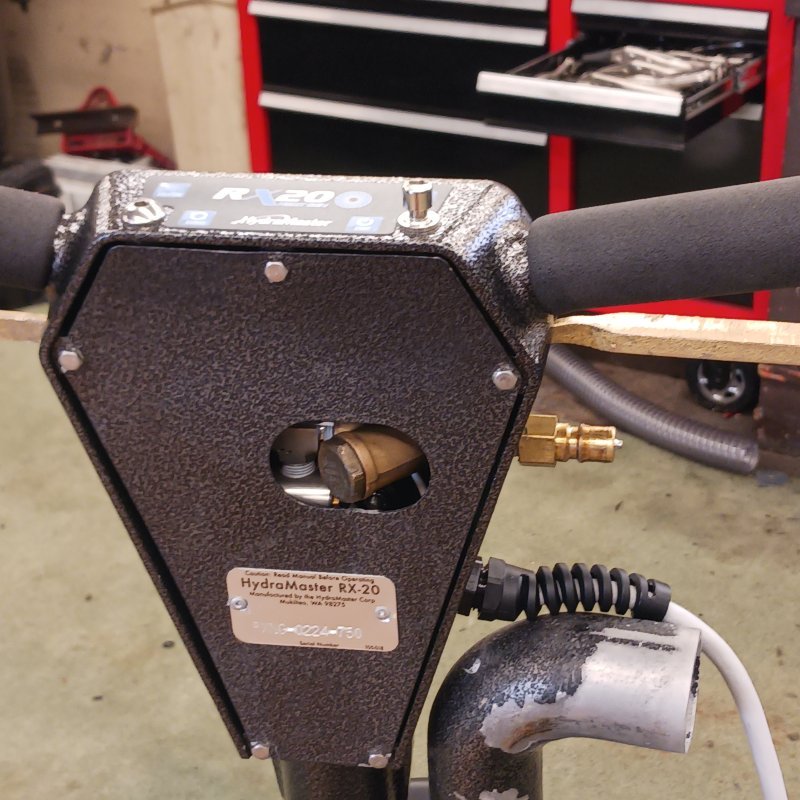

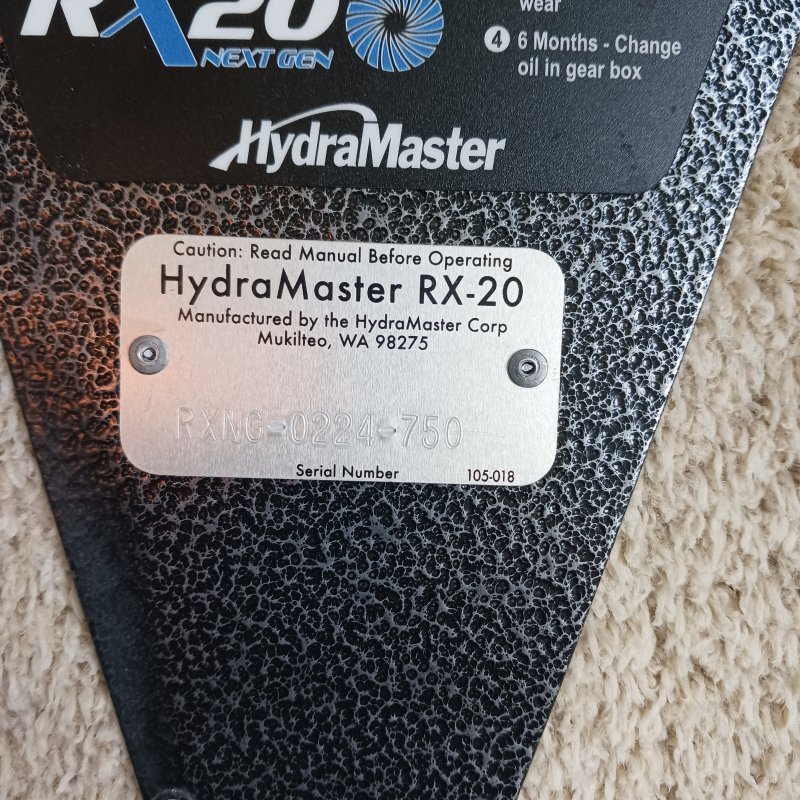

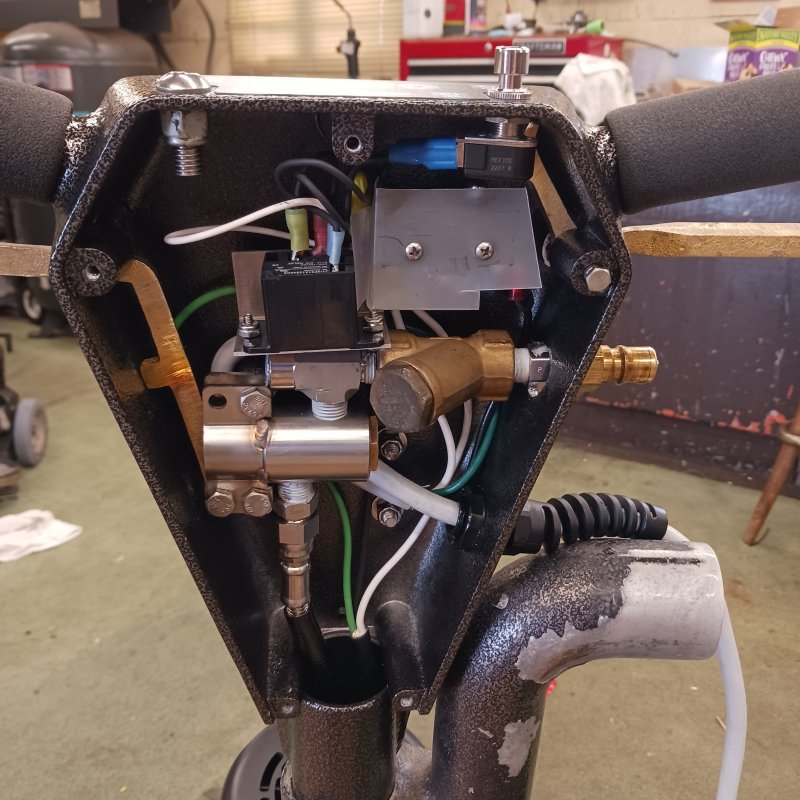

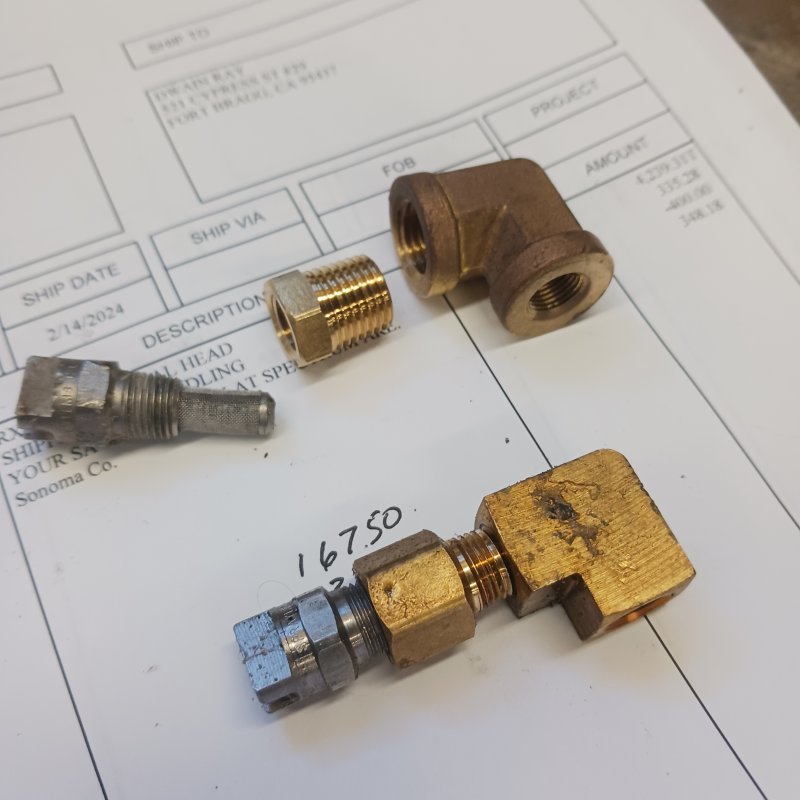

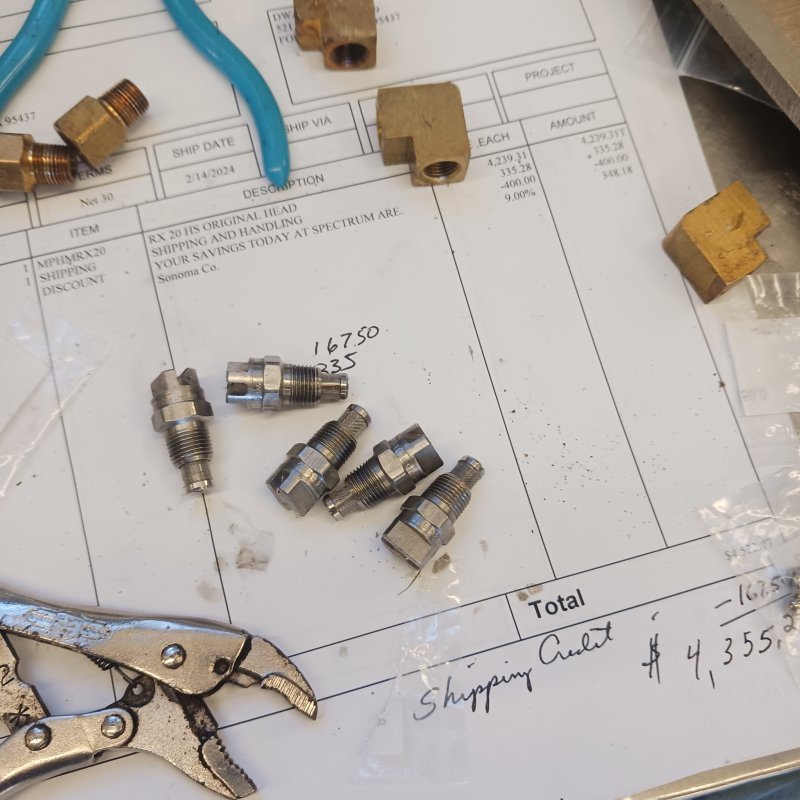

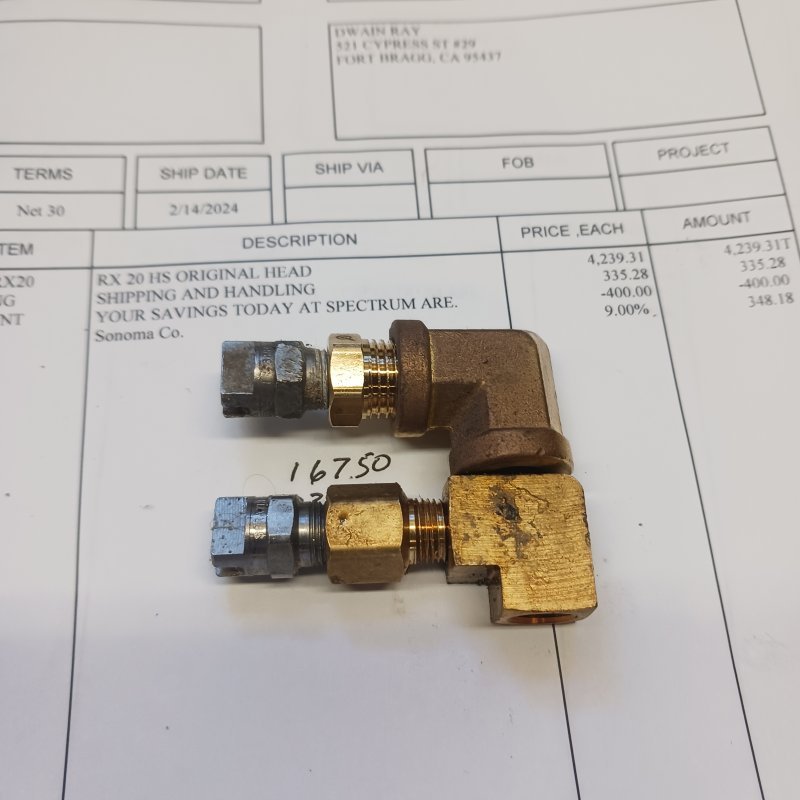

Ive run rx20's for about 30 years now i still have one of the first made in my storage shed. Last year i bought a new nexgen, i bought it for the handle. Not because my old one didn't work. Over the decades there has been many changes made to the rotary. Till now most were good.as i said in the beginning i bought the new one for the handle. In the past the locking mechanism has been a tension based system and soonest or later it slips on the last generation hydramaster came up with a fix to the problem by putting brass plugs in the side so as to be able to tighen the tension. They sold the plugs as a kit to retro fit older models. The new handle on the nextgen fixed that with a positive locking system love love it and the engineers should have stopped there. But NOOOO if they did they would be outa a job so in there infinite wisdom they went on. First they made a useless wand to vacuum corners . But inorder to do that they firts reduced the vacuum hose size from2" off the star totjis magnificent wand then further reduce vacuum to 1.25 " thru the breakable plastic tube then back to 2" out wtf!!!. No wonder they went to 3 jets and re designed the heads to have smaller vacuum slots . That was the first thing to go on mine!! And i used off the shelf hydramaster parts to fix the problem. I went to my storage shed and robbed a bolt on vacuum tube off an old low speed rotary and bolted it on the new one works great 2" all the way hydramaster if you're reading this my suggestion is to offer it as maybe an option YOU CAN CALL IT MAX VAC PACK I know some of the kids today want the toy wand but for those of us that want the power at least make the parts available