Mark Saiger

Mr Happy!

- Joined

- Dec 26, 2006

- Messages

- 11,200

- Name

- Mark Saiger

Been a little nitch I have been doing for awhile. Not a lot of calls, but when I am needed, we have figured out how we can heat up the lines, scan them and find potential breaks.

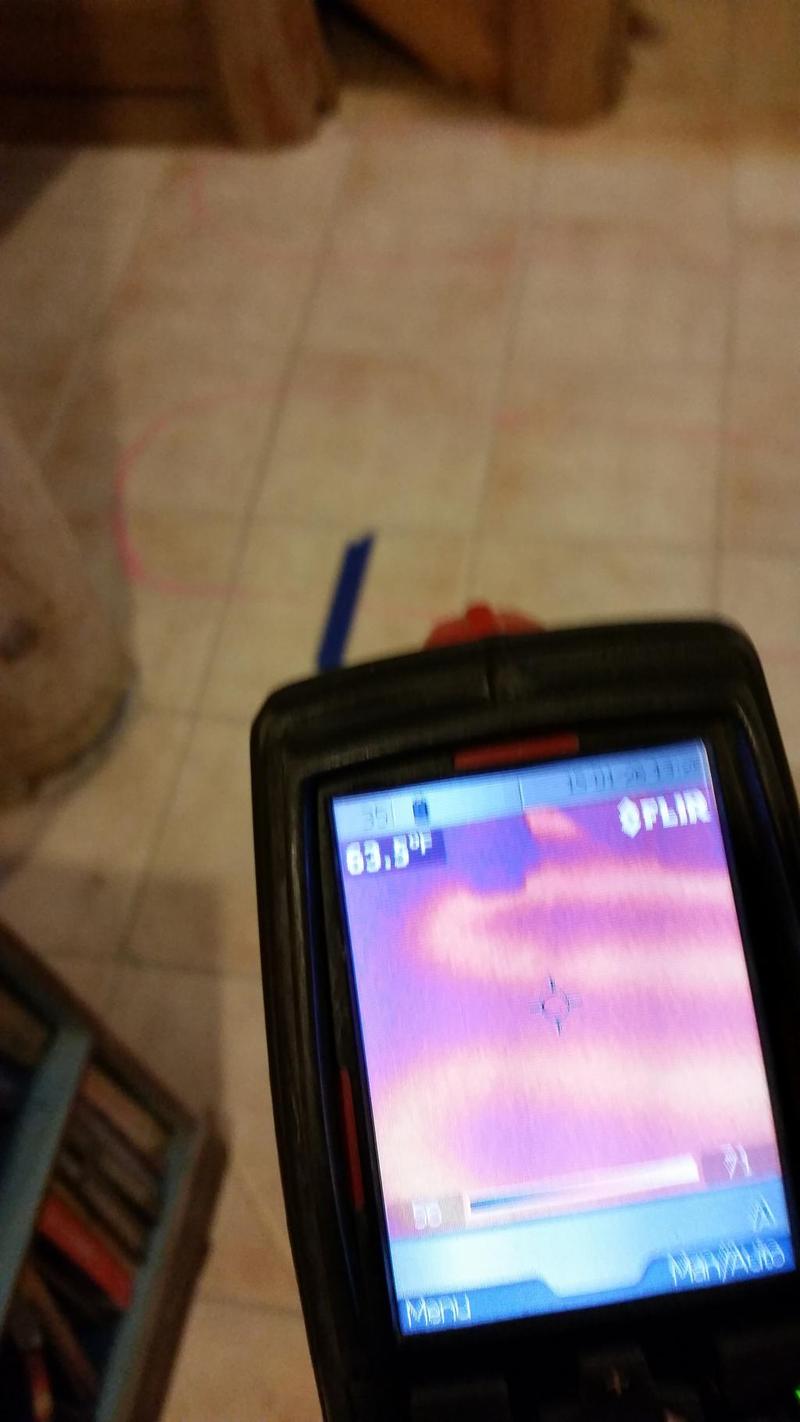

This floor today had 3 separate heat runs (reason for the different colored chalk)

The first run took over 30 minutes to get to pop up on the camera, the other 2 runs were a bit easier.

There are approximately 12 plus breaks in this floor.

Insurance company will have to figure out with the client how to proceed.

I imagine, they are going to have the spots we discovered tore apart (Jackhammer) and spliced, then pressure test and go from there, or tear it all out.....or try to buy the clients off and install other heat source.

There is an antifreeze you can run in these (which I have in mine) that can prevent this, but the installer said it would take away from better heating (actually there is a mix ratio so you don't rob the heat)

Procedure

Our Butler Truckmount set the psi down to 10 or so psi (not over 20)

Heat was at max yet, but truckmount only on idle and only producing about 200 degrees (hose rated for about 145 degrees) but with loss of heat to entrance point, no problem.

Hook up a connector to each heat loop, put your suction on the other end.....and start the process.

We then used chalk to mark the lines, used Blue tape to mark potential spots that are broken.

We use different colored chalk for each heat loop to help separate out and also for insurance company and adjuster review. The blue tape is areas we marked of suspected line breaks. They are very bright on the thermal cam and like pin hole spikes.

Video shows a bit, but we bill $200 per hour....we will bill $1200 plus tax today.

Was a 2 hour drive round trip.

It took about 150 gallons of water today to heat and scan these 3 heat loops.

Mark Saiger

www.Saigers.com

"Bring on the Blue!"

This floor today had 3 separate heat runs (reason for the different colored chalk)

The first run took over 30 minutes to get to pop up on the camera, the other 2 runs were a bit easier.

There are approximately 12 plus breaks in this floor.

Insurance company will have to figure out with the client how to proceed.

I imagine, they are going to have the spots we discovered tore apart (Jackhammer) and spliced, then pressure test and go from there, or tear it all out.....or try to buy the clients off and install other heat source.

There is an antifreeze you can run in these (which I have in mine) that can prevent this, but the installer said it would take away from better heating (actually there is a mix ratio so you don't rob the heat)

Procedure

Our Butler Truckmount set the psi down to 10 or so psi (not over 20)

Heat was at max yet, but truckmount only on idle and only producing about 200 degrees (hose rated for about 145 degrees) but with loss of heat to entrance point, no problem.

Hook up a connector to each heat loop, put your suction on the other end.....and start the process.

We then used chalk to mark the lines, used Blue tape to mark potential spots that are broken.

We use different colored chalk for each heat loop to help separate out and also for insurance company and adjuster review. The blue tape is areas we marked of suspected line breaks. They are very bright on the thermal cam and like pin hole spikes.

Video shows a bit, but we bill $200 per hour....we will bill $1200 plus tax today.

Was a 2 hour drive round trip.

It took about 150 gallons of water today to heat and scan these 3 heat loops.

Mark Saiger

www.Saigers.com

"Bring on the Blue!"