You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wand Flow Rates

- Thread starter Sonrise1

- Start date

FyreLyter

Supportive Member

- Joined

- Jun 24, 2011

- Messages

- 241

- Name

- Steven Dillon

Correct me if I am wrong but the numerical value of what flow you are running is based off how many gallons per minute will flow out of a given orifice at (I think this is right) 4000psi.

Your jets will have each there own flow rates and then you combine them to make up your ending flow number.

when we say 9 flow however it does not fully correlate to 9 gallons per minute truly coming from the wand since we do not run our pressure at 4000 psi.

Your jets will have each there own flow rates and then you combine them to make up your ending flow number.

when we say 9 flow however it does not fully correlate to 9 gallons per minute truly coming from the wand since we do not run our pressure at 4000 psi.

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,120

High Flow wands, more water or just faster?

Seeing how the 12, 16 and 24 flow fad is over, what have you old timers who were here for the Greenie Revolution, settled on flow wise? Sure 12 and above let you move the wand faster and flush deeper without as much need of agitation, but at what price? Less heat unless you bought a...

FyreLyter

Supportive Member

- Joined

- Jun 24, 2011

- Messages

- 241

- Name

- Steven Dillon

I like you

High Flow wands, more water or just faster?

Seeing how the 12, 16 and 24 flow fad is over, what have you old timers who were here for the Greenie Revolution, settled on flow wise? Sure 12 and above let you move the wand faster and flush deeper without as much need of agitation, but at what price? Less heat unless you bought a...mikeysboard.com

Dolly Llama

Number 5

- Joined

- Oct 7, 2006

- Messages

- 31,225

- Name

- Larry Capitoni

Correct me if I am wrong but the numerical value of what flow you are running is based off how many gallons per minute will flow out of a given orifice at (I think this is right) 4000psi.

correct, but believe the psi/flow rate calc used by jet manufactures is at 40psi

If I recall without googling, an 01 jet flows 1 tenth GPM @ 40psi

but not sure if it's lineal ....cause I don't "think" an 01 jet flows 10gpm @ 4000psi

..L.T.A.

BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,569

- Name

- Matt w.

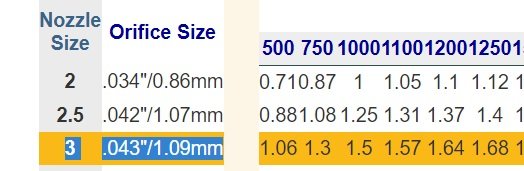

Nozzle Calculator - Giant Pumps

This chart will assist you with the selection of the proper nozzle size. To find the correct nozzle size you need to know the flow of your system and the pressure you wish to achieve. First, select the column with the required pressure across the top, then read down the column to find the amount

BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,569

- Name

- Matt w.

Can you tell use what machine you’re using on that wand?I need you all to help me understand "flow" as it relates to carpet wands. I understand that higher flow results in more water, but how much. When you say "my wand is 9 flow" what do you mean?

F

FB19087

Guest

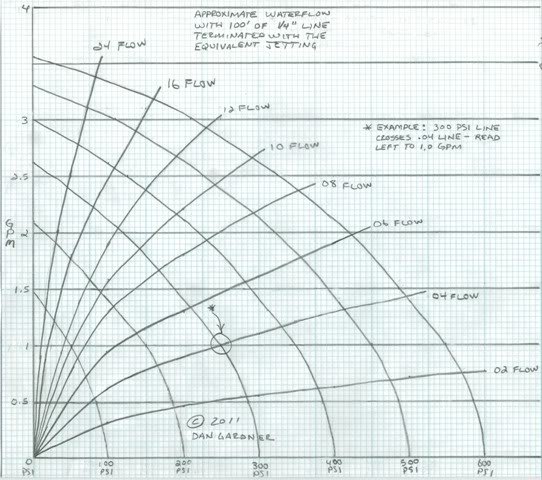

Boring Flow Techie Stuff

I posted this on another board, mainly to help the less experienced folks out there. Not sure if any of you seasoned vets can use it, but just in case, I'll post it here too. First up is a standard nozzle flow chart. It seems every time I need a value, the charts out there don't list it. Maybe...

(corrected for friction loss by Dan G)

FyreLyter

Supportive Member

- Joined

- Jun 24, 2011

- Messages

- 241

- Name

- Steven Dillon

I like being a meatheadDon’t listen to those meatheads above. Just follow the chart to the specs on your water pump on how much gpm it can put out

Lee Stockwell

FOJL

- Joined

- Oct 7, 2006

- Messages

- 18,851

- Name

- Lee Stockwell

I miss Dan G

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,230

- Name

- Ron Marriott

We refer to flow as it relates to the size of jets you have on the wand. 3-11003 jets will give you a 9 flow. 2-11003 jets will give you a 6 flow and so on. Has nothing to do with GPM, it's just the size of the jet or jets.I need you all to help me understand "flow" as it relates to carpet wands. I understand that higher flow results in more water, but how much. When you say "my wand is 9 flow" what do you mean?

F

FB19087

Guest

I guess in the sense that we refer to it......meaning not usually having any idea how much....or at any standard pressureWe refer to flow as it relates to the size of jets you have on the wand. 3-11003 jets will give you a 9 flow. 2-11003 jets will give you a 6 flow and so on. Has nothing to do with GPM, it's just the size of the jet or jets.

but that last # in the jet size it what it will flow in gpm @ 40 psi. Each of those 1103 jet would produce .3gpm at 40 psi (not particularly useful info for our application)

increasing with psi.............as per chart above

Last edited by a moderator:

steve_64

Member

- Joined

- Aug 11, 2012

- Messages

- 13,372

Coming from the machining industry I agree with Ron.

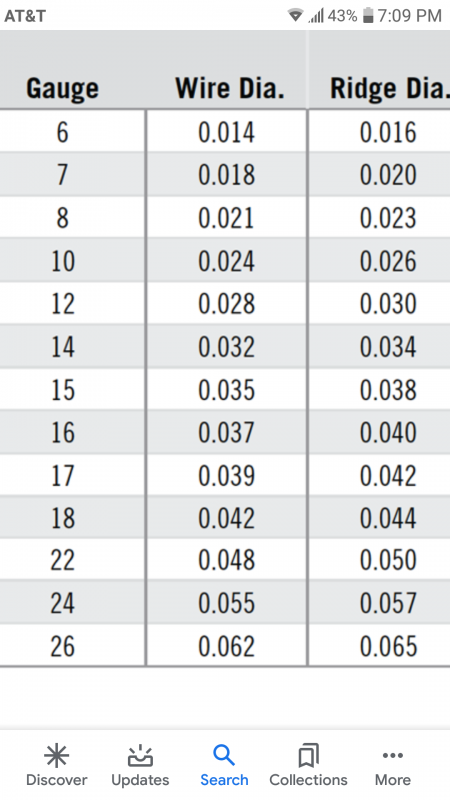

A 11003 is a .030 opening. The 110 is the angle. You can't get a .030 tip cleaner in .015 opening. Different pumps will produce different flow rates at equal psi. At least in my experience.

Think of using an electric sprayer compared to your truckmount. The smaller the pump the less water you get through the same orifice.

It's about the back pressure.

A 11003 is a .030 opening. The 110 is the angle. You can't get a .030 tip cleaner in .015 opening. Different pumps will produce different flow rates at equal psi. At least in my experience.

Think of using an electric sprayer compared to your truckmount. The smaller the pump the less water you get through the same orifice.

It's about the back pressure.

steve_64

Member

- Joined

- Aug 11, 2012

- Messages

- 13,372

Guess my welding cleaner tips are wrong. I use the .015 for just that.

I'll have to mic them someday to see if that's accurate.

But yes it appears I may be wrong on that.

Last edited:

Dolly Llama

Number 5

- Joined

- Oct 7, 2006

- Messages

- 31,225

- Name

- Larry Capitoni

Coming from the machining industry I agree with Ron.

A 11003 is a .030 opening. The 110 is the angle. You can't get a .030 tip cleaner in .015 opening. Different pumps will produce different flow rates at equal psi. At least in my experience.

Think of using an electric sprayer compared to your truckmount. The smaller the pump the less water you get through the same orifice.

It's about the back pressure.

..L.T.A.

steve_64

Member

- Joined

- Aug 11, 2012

- Messages

- 13,372

Yeah yeah yeah. I really thought that's what it was. Guess Fred taught me better. I will measure it some day if I think about it when I have my tools out.

steve_64

Member

- Joined

- Aug 11, 2012

- Messages

- 13,372

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,505

- Name

- sam miller

Wow cool

Just got a new Aerotech. It flows 6gpm up to 1600 psi. We run our wands at 300, zipper at 500.Can you tell use what machine you’re using on that wand?

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,230

- Name

- Ron Marriott

Nothing wrong with running your wands at 500 psi.Just got a new Aerotech. It flows 6gpm up to 1600 psi. We run our wands at 300, zipper at 500.

Sierra Clean Care

Member

- Joined

- Jun 20, 2016

- Messages

- 6,563

- Name

- Jeff T

To really bring things into perspective, get a 5 gallon bucket.

Mark off in 1 gallon increments.

Get a stop watch.

Set up as you would to clean.

Trigger wand into bucket, start the timer.

Simple.

Then YOU know EXACTLY what you are cleaning at....

Forget the friggin charts, use a bucket.....

Mark off in 1 gallon increments.

Get a stop watch.

Set up as you would to clean.

Trigger wand into bucket, start the timer.

Simple.

Then YOU know EXACTLY what you are cleaning at....

Forget the friggin charts, use a bucket.....

hogjowl

Idiot™

- Joined

- Oct 7, 2006

- Messages

- 49,947

You make me nervous

Latest posts

-

-

-

-

-

-

Suggestions for removing strong VOC smell from concrete slab?

- Latest: MasterCarpet

-

-

-

-

-

-

-