Larry Cobb

Member

Brent;

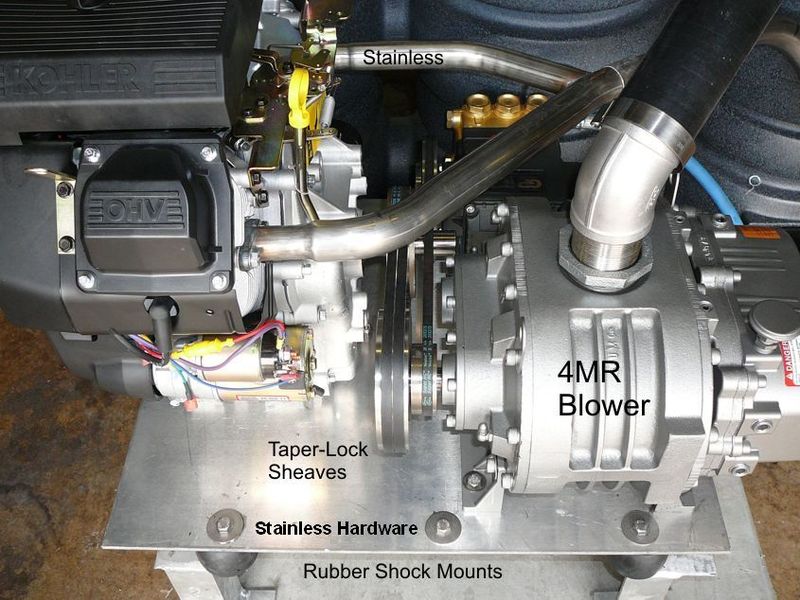

Here is another picture from the side showing the belt drives and mounting plate layout:

This TM has the new design #4MR blower with the space between the gearbox and the lobe housing.

Larry

Here is another picture from the side showing the belt drives and mounting plate layout:

This TM has the new design #4MR blower with the space between the gearbox and the lobe housing.

Larry

:wink: :idea: :shock:

:wink: :idea: :shock: