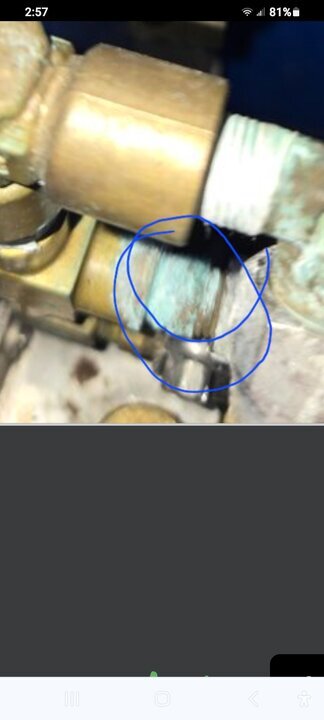

I'd love that Dwain, very kind offer thanks bud! Yea I think I have the same setup you took in the pic. I'll confirm tomorrow. Thanks for heads up about the weak point in the system too, and a lasting solution!

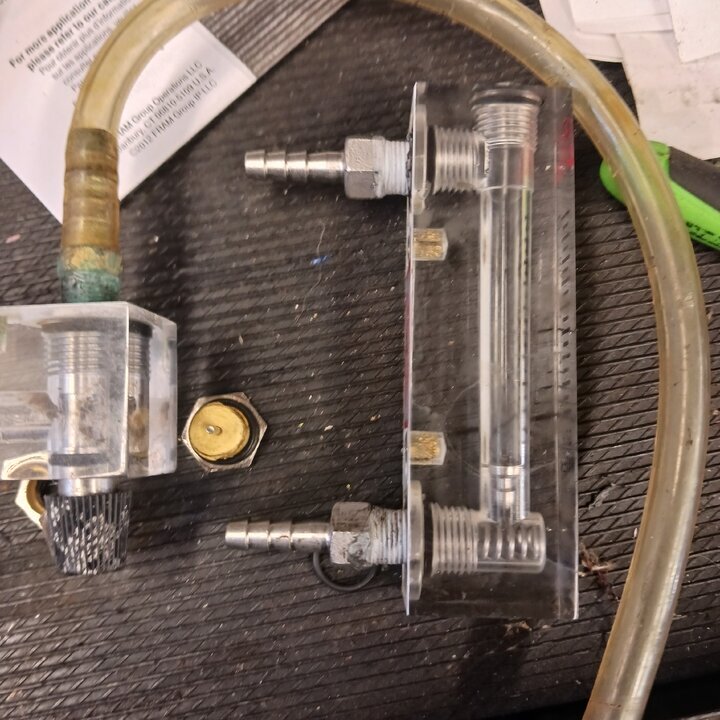

Stainless is the way to go eh. I wonder about quick connects though, it seems like they go for other reasons so would it be wasteful to spend the money on them or do they really last? Exciting times. I need to get a pile of hoses and a box of fittings. I am impressed with the selection at my local hardware store, they have a wall of brass fittings that will fit a decent amount of my needs.