Ray Burnfield

Supportive Member

- Joined

- Apr 4, 2013

- Messages

- 821

- Name

- Ray Burnfield

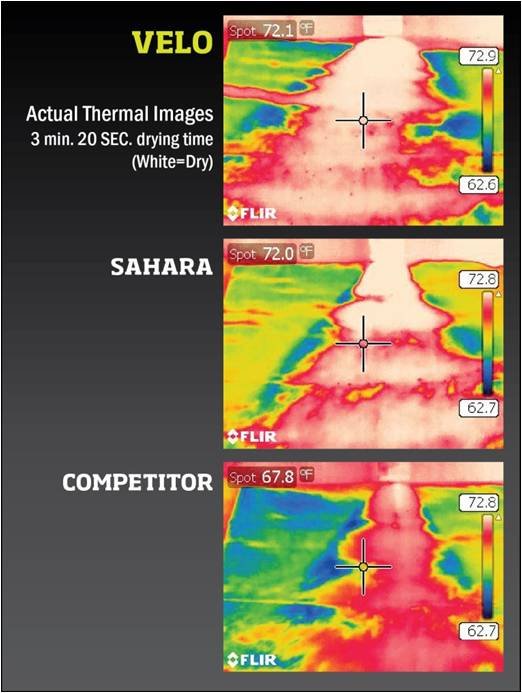

The Velo will dry surfaces faster than their X-3 Turbo drier which has more CFM. The design on the Velo uses the air developed more efficiently with much less wasted air movement.I don't get it, I don't want lower cfm no matter how well it stacks.

I blame the franchises. They dictatate whats being built and sold because they buying the large volume of drying equipment.

Since the majority are smaller operations they design stuff for one man carry and tight space in a van.

It was designed by a Boeing engineer. Think of a water hose when you put your thumb over the end restricting the flow increasing the pressure.