You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Titanium wand jets,

- Thread starter steamron

- Start date

On most of my wands i found if you slighty angle the jets you can eliminate overspray and streaking (in the middle where 2 jets spray patterns hit one another)I have a Prochem titanium wand, wondering if anyone one changed up the jets to fit their needs or preference. What are they?

I don't like the slight over spray one each end.

BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,599

- Name

- Matt w.

I think 80 degree jets are good if you don’t have jet extenders. What’s the current angle on the outside jets?

Kenny Hayes

Member

- Joined

- Apr 17, 2009

- Messages

- 10,059

- Name

- Kenny Hayes

Even the old Jimmy Bane wand would do that at 150 psi

BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,599

- Name

- Matt w.

80015= 80degree spray and 1.5flow x 5= 7.5flow of water

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,514

- Name

- sam miller

Four jet would probably be 11002 in the middle and 9502 on the ends.I have a Prochem titanium wand, wondering if anyone one changed up the jets to fit their needs or preference. What are they?

I don't like the slight over spray one each end.

6 jets would the same except add two 9502 in the other ports,

In the 6 jet you could drop to 9501.5 and 11001.5 jets to reduce to 9 flow instead of 12 flow.

SamIam

Member

- Joined

- Aug 9, 2012

- Messages

- 11,514

- Name

- sam miller

Well the jet is off the carpet if it's the mach 15 with no extenders so that's probably good.The only wand I know of that’s a 5 jet is a pmf mach15

You can tell if it flushes good or not and make changes if needed

Nate The Great

Member

- Joined

- Mar 29, 2008

- Messages

- 9,752

- Name

- Nate W.

The only wand I know of that’s a 5 jet is a pmf mach15

CMP aka GreenHorn has 5 jets, I believe Joe. B sells a jet manifold that would convert your wand to another spray bar..

The side jets are slightly turned inwards to prevent overspray. The wand in the pic is used for residential carpets only, set at #9 flow- 95015. The identical wand is set to #11 flow for the commercial accounts. ( mostly CGD carpeting) Both are fitted with extenders to counter the glides.I have a Prochem titanium wand, wondering if anyone one changed up the jets to fit their needs or preference. What are they?

I don't like the slight over spray one each end.

The flow on that wand with 6 - 015 jets is between 1.8 &2.1 gpm@400psiThe side jets are slightly turned inwards to prevent overspray. The wand in the pic is used for residential carpets only, set at #9 flow- 95015. The identical wand is set to #11 flow for the commercial accounts. ( mostly CGD carpeting) Both are fitted with extenders to counter the glides.

View attachment 133176

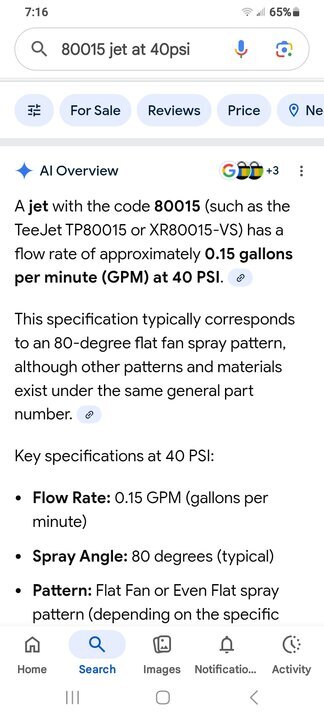

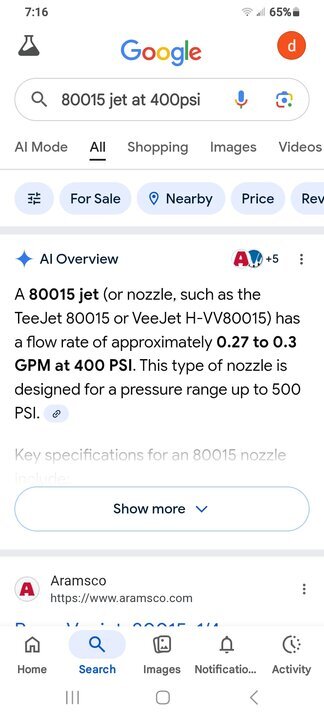

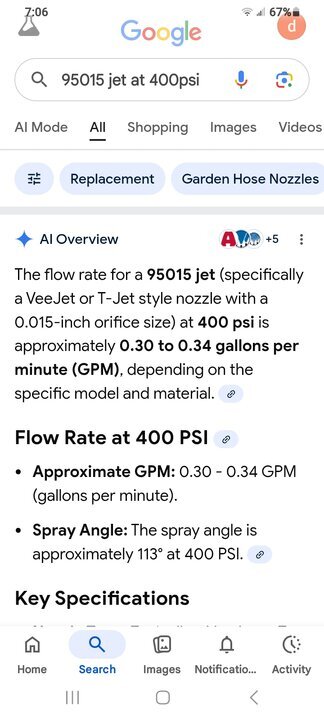

You would have to recalculate for the 3/8" solution hose again, if you want to be so factual. It's possible that we used to mistakenly refer to jet opening as flow, e.g., 6×9502 would equal to #12. I promise to give you exact numbers once I have more time and do the bucket testFlow is based on psi. Most spray jets are rated at 40psi. Based on that, 5 - 80015 jets will flow .75 gpm @40 psi (.15gpm per jet×5) and 1.35 to 1.5gpm @400psi

View attachment 133179 View attachment 133180

hogjowl

Idiot™

- Joined

- Oct 7, 2006

- Messages

- 49,981

I like it.

Cleanworks

Moderator

- Joined

- Oct 22, 2012

- Messages

- 28,244

- Name

- Ron Marriott

The 4 flow is a nice compromise. I can use it with my 500 psi portable, which gives me more like 400 psi on a 4 flow or on the truck mount. I don't notice any real difference from my 6 flow wands. I feel the shear angle helps.It's all sort of meaningless and just a benchmark to start from

@hogjowl have you come to an opinion on the Chosen's four flow yet?

I have no idea what you're talking about. Ive always simply used spraying systems flow charts for flows based on tip size and pressures , then simply multiplied by number of jets to reach flow. Flow is based on size of tip and psi at tip. Diameter, construction (materials its made of),and length of hose will cause pressure drop from pressure source to tip which will effect actual flow. Thats why jets are measured on a chart at a standard pressure generally 40psi and adjusted up or down from base for final flow. And all this is made sooo much easier for this computer generation by simply asking google "whats the flow rate of a _ _ _ _ # jet @ _ _ _ _ psi and getting an immediate answer. To get an accurate pressure reading at the tip , youll need a pressure guage on quick connects at the wand and check pressure while spraying. But if you're really really really geeking out and you have a hose connecting your trigger valve to jet manifold youll connect the guage where the manifold and hose meet for the utmost accurate reading. If that's your thing and you got that much spare time. For me .... size & number of jets and pressure at the trigger is good enough. I have a" lie detector " that looks like picture below i use as a test tool for checking my temps & pressureYou would have to recalculate for the 3/8" solution hose again, if you want to be so factual. It's possible that we used to mistakenly refer to jet opening as flow, e.g., 6×9502 would equal to #12. I promise to give you exact numbers once I have more time and do the bucket test.

Last edited:

Kenny Hayes

Member

- Joined

- Apr 17, 2009

- Messages

- 10,059

- Name

- Kenny Hayes

Too much work!

jeffexe

Member

- Joined

- Feb 16, 2021

- Messages

- 197

- Name

- jeff

Hey Mike. I use the Chosen wand daily and switch back and forth from the hole glide to the slot glide. I find the hole glides give faster dry times, especially on longer residential fibers and dense carpets like anything goes styles. I prefer the slot glide on commercial carpets. The hole glides also make cleaning throw rugs much easier too.with the Hole glide have your dry times been reduced from you other 6 flow hole'd wands?

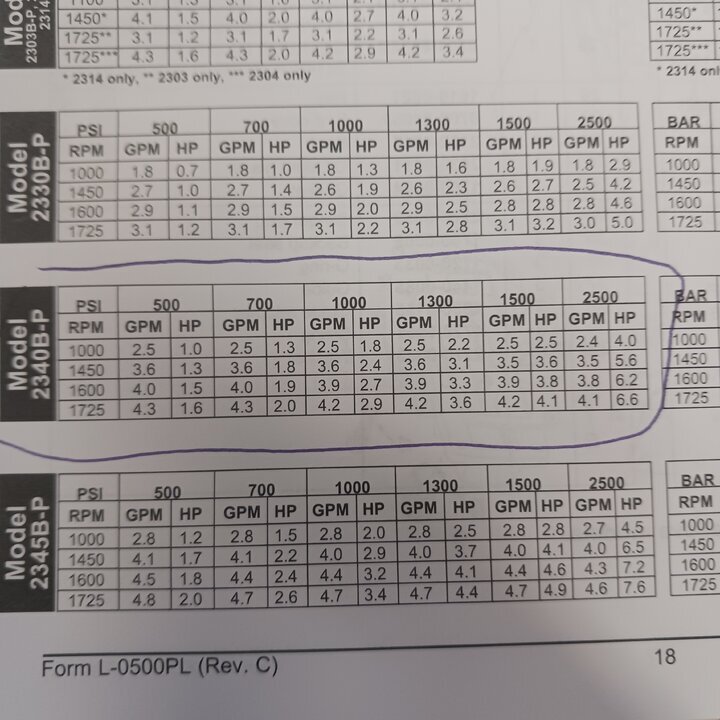

Yes thats what im saying . But only if your jets are allowing LESS THAN YOUR PUMP OUTPUT IS youll spray the same amount of water ei: if your pumps flow is 2gpm@ 400 psi and your jets are 1.5gpm @ 400psi the flow would be the same even on a pump that did 15 or 20 gpm. However if the pump does 2gpm@400psi and your jets use2.25gpm@400psi there would be a severe pressure drop on that pump but would maintain pressure on the pump that produces 4gpm. Keep in mind pumps are rated @rpms ie: if your pump is rated @ 2gpm@2500psi@1750 pump rpm if the pump turns less rpms the gpm and psi will be lower. Below is the performance chart for my pump, Hypro 2340b-pSo you're saying a pump that has a max flow of 2 gpm will put down the same amount of water as a pump with 4 gpm with the same set up?

Last edited:

jeffexe

Member

- Joined

- Feb 16, 2021

- Messages

- 197

- Name

- jeff

Mostly because they are not vacuumed well. I noticed on some commercial jobs with uneven concrete floors under the carpet that it streaks more than slot. Not sure why but it just does. in a perfect world, i would use the hole glides on every job.why is that?

Mikey P

Administrator

- Joined

- Oct 6, 2006

- Messages

- 117,173

plugged holes most likely...Mostly because they are not vacuumed well. I noticed on some commercial jobs with uneven concrete floors under the carpet that it streaks more than slot. Not sure why but it just does. in a perfect world, i would use the hole glides on every job.

Hard to see if installed

The 4 flow is a nice compromise. I can use it with my 500 psi portable, which gives me more like 400 psi on a 4 flow or on the truck mount. I don't notice any real difference from my 6 flow wands. I feel the shear angle helps.I have no idea what you're talking about. Ive always simply used spraying systems flow charts for flows based on tip size and pressures , then simply multiplied by number of jets to reach flow. Flow is based on size of tip and psi at tip. Diameter, construction (materials its made of),and length of hose will cause pressure drop from pressure source to tip which will effect actual flow. Thats why jets are measured on a chart at a standard pressure generally 40psi and adjusted up or down from base for final flow. And all this is made sooo much easier for this computer generation by simply asking google "whats the flow rate of a _ _ _ _ # jet @ _ _ _ _ psi and getting an immediate answer. To get an accurate pressure reading at the tip , youll need a pressure guage on quick connects at the wand and check pressure while spraying. But if you're really really really geeking out and you have a hose connecting your trigger valve to jet manifold youll connect the guage where the manifold and hose meet for the utmost accurate reading. If that's your thing and you got that much spare time. For me .... size & number of jets and pressure at the trigger is good enough. I have a" lie detector " that looks like picture below i use as a test tool for checking my temps & pressure

View attachment 133212

The above is a

Cleanworks reply to Mikey. Now, I'm really confused about what 4 flow and 6 flow mean